If you haven’t seen it and are considering a GridBot build, check out this ongoing documentation and discussion.

Awesome! Thanks for linking that post. And I love the new forums. I hope to see some great projects on here.

I link to your build thread anytime anyone shows interest in a GridBot. It really is fully of incredibly good information and eye candy.

I expect some inertia getting people over from Facebook. Communities are best built by word of mouth, so please invite whomever you think would be interested. But this really is a better experience. I wish I had done it sooner.

I have my printer on a table, at desk height. I really love how easily I can see the print when it is making the first layer. It is at a really comfortable height, and it is very open. I feel like this is an underrated feature.

Since I was not interested (from experience) in printing ABS, I was able to focus on making it as open and light as possible while keeping the XY rigid. Did putting the cross braces under the bed make any noticeable difference for you?

I didn’t notice anything different.

On my printers, their primary purpose is to mount the 3 level thumb screws. The way they are printed prevents them from torquing under load.

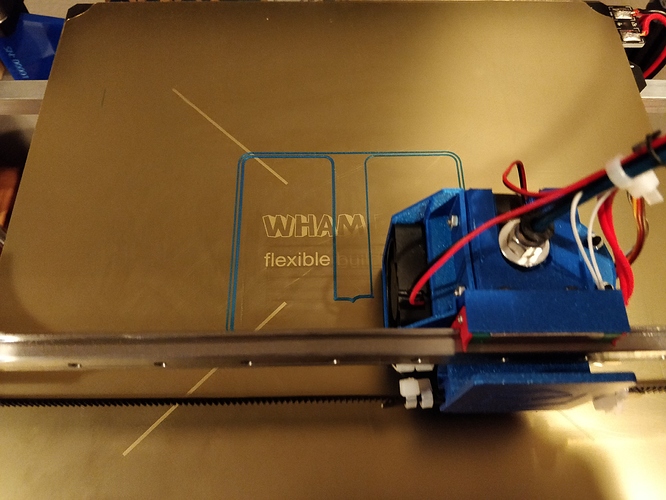

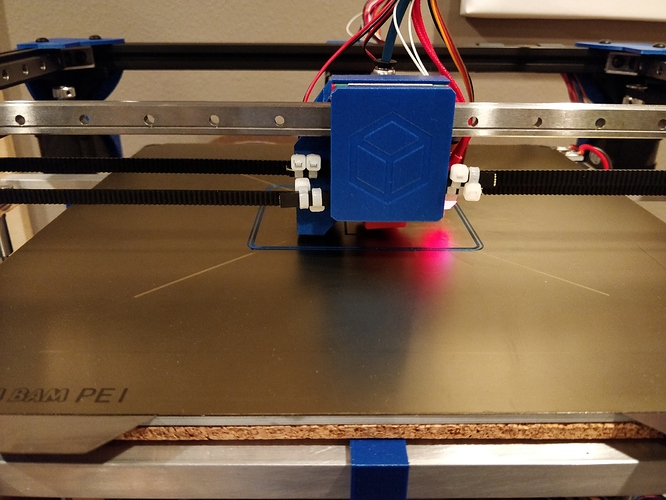

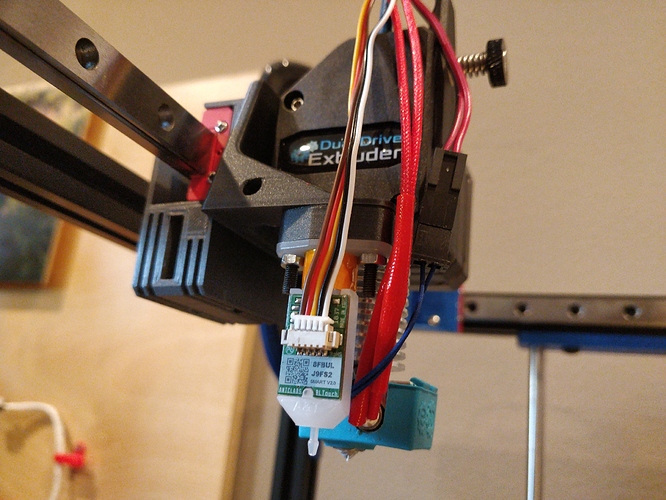

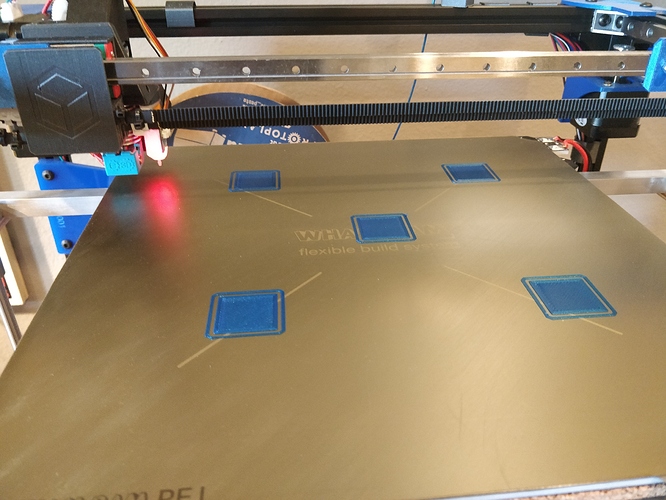

I’ve been reworking the gantry pieces to mount the extruder direct drive. I think I have a good design and it seems to work well. But I am still having trouble with adhesion. I am wondering how many of my issues have been related to this wham bam pei. It just isn’t sticking like it should.

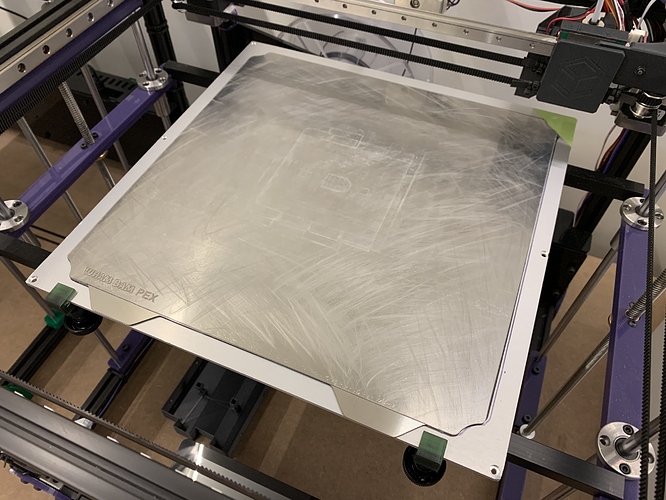

I really want to like this magnet pcb bed. But I am once again looking at an alternative. The rail core vendors sell some very nice beds, but they are $$$. I really like the removable spring steel, but maybe I will have to give that up and just scrape stuff off.

I had to sand the PEI of the Wham Bam plate to get stuff to stick.

Any pics of your gantry work? I’m thinking about trying some new ideas in the next build.

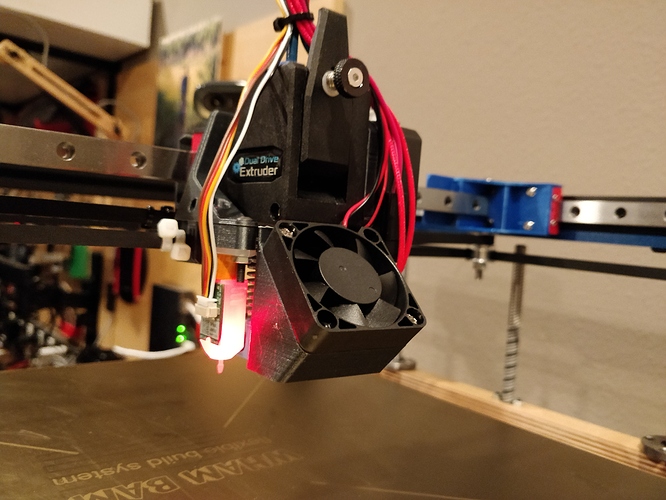

The first part attaches to your existing bearing mount. It hugs the extruder and fits between the extruder and motor. The bl touch needs to be about 7mm lower, so I just printed a spacer. The part fan and cooling fan both attach to the v6 heatsink. I do plan on releasing these files. The extruder mount was designed by a friend and I haven’t gotten good testing in yet. So I don’t want to release them until I have some decent results.

It has to be assembled in order and it is a little tricky getting the screws for the extruder in.

It is really hard to photograph

excellent. thanks. if I do end up making a direct drive mount, I will publish a new CAD document with it.

That steel wool did wonders. I was skeptical but the same gcode was a mess and then worked flawlessly. No tuning in between:

I also switched filaments to the blue stuff and it made an improvement. Now I need to put the white atomic back in and see how well that works with a scrubbed plate.

Thanks again.

I was surprised that the PEI had no texture. That’s often critical for PLA so it can flow-in, crystalize, and grip the surface.

@jeffeb3 what was your reason for switching to direct drive? I have used both and I don’t have a clear preference (for my applications). That’s why I just went with the Bowden for the GridBot.

Your gantry looks good though.

I was having a lot of trouble dialing in the retraction and linear advance settings. My other printer prints great with a direct drive, so I just wanted to use what I know.

I was seeing things like the PTFE tube bend and move when there was a retraction, which just lead me to believe it wasn’t a very tight fit, and it was causing errors in the print.

This is working, but I’ll need to print a lot more to know if it is better. Right now, I would give it at least a passing grade  .

.

https://www.prusaprinters.org/prints/41498-gridbot-direct-extruder-mount

Ryan drew the mount originally in onshape (I think he thought it would be a fun challenge to try onshape, but he didn’t have any of the parts). I made a few changes, and added the rest of the parts. I exported the step files because you don’t want to see how I cad. I published them all as is at prusa printers, but I’m more than happy for you to do what you’d like with them.

I’m not sure the part fan is as good as it could be. I also still wish I had an LED somewhere in there. So I may revisit that fan part later. That was the one derivative part, because I cut off one fan from a dual fan mount.

Cool. Can you provide links to the clone bmg extruder and pancake motor you used?

Hello comrades! Collecting GridBot2. Tell me the table set. Aluminum base, heated, printing surface. I read a lot, I want the best option.