if the hole for the M5 bolt is oversized, that could be a problem. it should be snug. I do have an M5 washer under the idlers.

One solution for an oversized M5 bolt hole in the acrylic is to 3D print a piece that goes under the plate with tighter M5 holes. Then use longer M5 bolts. If that piece is relatively solid and thick, it will provide the stiffness and alignment you may be missing.

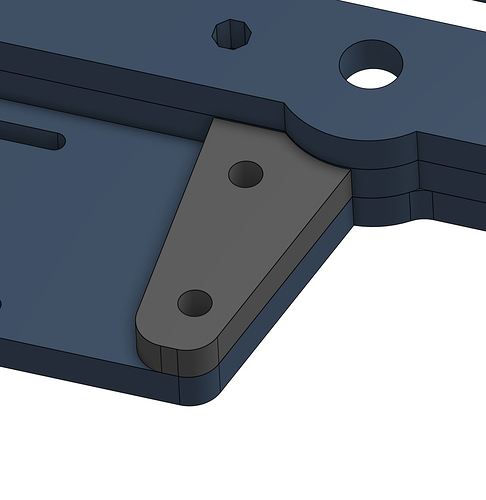

I added a “stiffener” part to the CAD model if you feel you need to try this. Easy to 3D print and add after the fact.

That’s a great idea. I will try that.

thinking about this more, it may not work unless you glue or otherwise anchor it to the acrylic.

You are right. I thought about doing that, but I think I found another solution now.

Since the bare screw only had a very slight wobble in the hole but otherwise held on ok, I just applied a couple of layers of PTFE thread sealer tape to the area. Now the screw is very stiff and with the assembly put together again the idler is turning well too.

I’ll keep an eye on this and might revisit the stiffener if it doesn’t hold up otherwise. But it’s looking good.

even better. simplicity.

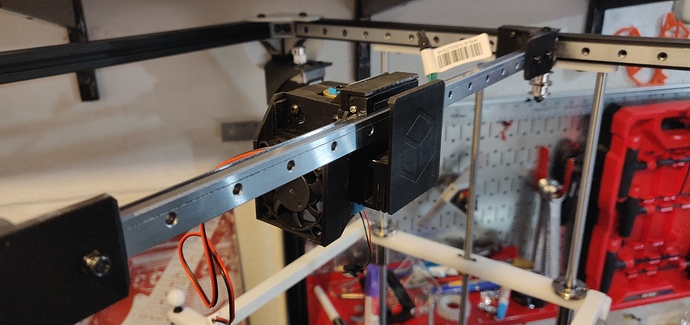

Ah. The Z idlers. I did have some binding, and then I just decided I didn’t need quite as much tension on the belt. It just needs to stay in its home.

add a spacer between the gear and the bearing so that the gear doesn’t hit the acrylic. also, make sure the threaded rod does not hit the frame extrusion. both cases can cause unwanted binding.

I redid all the idlers and they all seem to be fine now and ready to go.

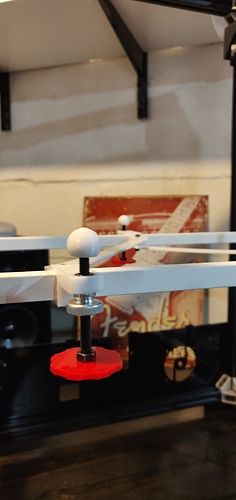

I also reprinted the level brackets because the others cracked slightly when I put the nuts in. I used white this time to match the rest of the carriage.

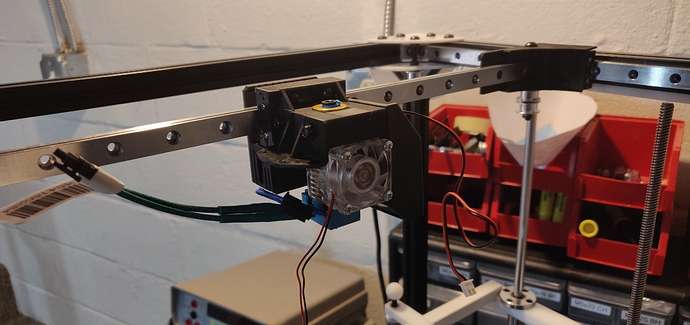

I added some additional thumb wheels to the level screws so I can easily lock them in place (see photo)

nice additions. I may add the thumb screws (or something like it) to the CAD model.

resin printed parts looking good

Hi guys!

I started ordering some parts for this build and hope to join you soon)

A small Q: is there any reason to pay a few extra $$ for the SKR v1.4 board?

SKR 1.3 should be fine.

1.4 gives you a few more interfaces for motors, LED, Wifi module etc that you won’t necessarily need. And the 1.4 Turbo has a slightly faster processor.

Here’s a comparison

Both not necessary, but since the price difference was marginal, I got the 1.4 Turbo

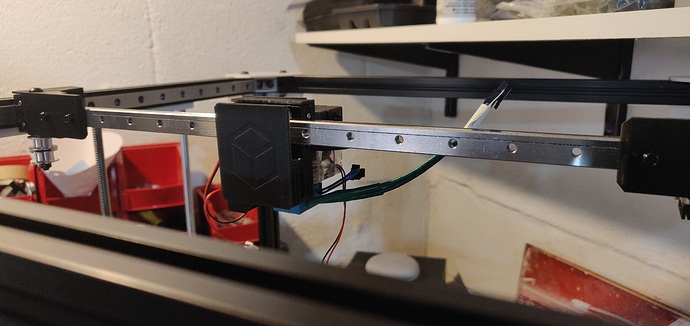

I haven’t posted any updates lately since I was busy with fixed around the house.

I’m currently working on the GridBot wiring and I’m doing a bunch of crimping. Not my favorite, but it has to be done. Hope to be able to make some more progress soon.

Wiring isn’t the hardest part of the build. But it is easily the most tedious.

I think you should just pick the one you want. They will all work, if you can configure them. If you choose the skr 1.3, it will be slightly easier, because Stewart has preconfigured firmware for it.

I don’t expect huge differences in firmware between 1.3 and 1.4 - but I might be wrong.

Thank you for your advice!

Preconfigured firmware is in this line?

define MOTHERBOARD BOARD_BIGTREE_SKR_V1_3

Or there some other lines that need to be configured for 1.3 to 1.4 replacement?