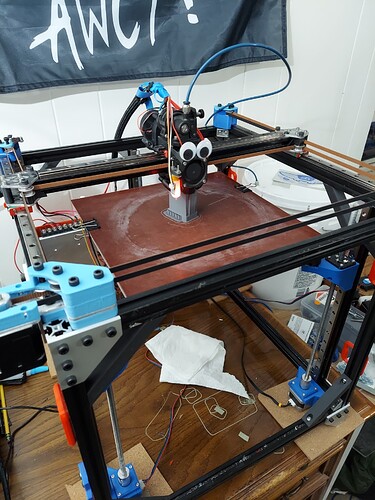

Howdy again, just now coming back to this having finally assembled and tested this. I’m not currently hosting the files anywhere, but I’d be happy share more details if you’d still like them. I still need to tweak the design to use the optical endstops stewart suggested. While it’s not really a Grid bot anymore, I tell anyone that asks how great of a place the gridbot is to start.

2 Likes