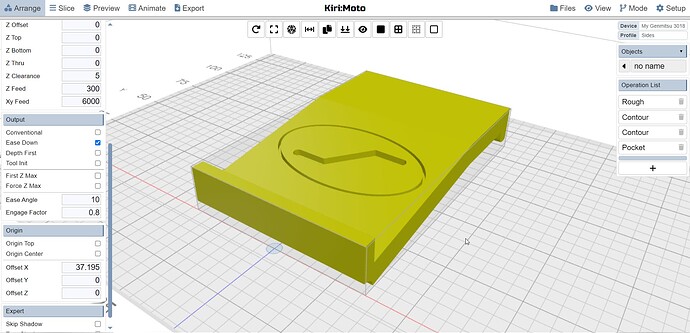

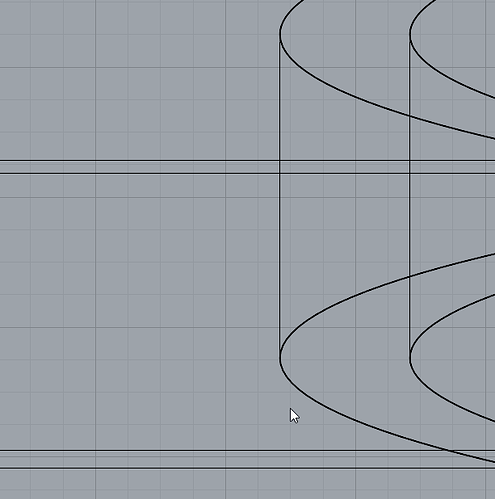

Hey all. I’m trying to decide on the best approach for this piece. It will be the lid of a box with a logo on the sloped face. I am planning on machining the top first but leaving the lip at the front so that it will still sit level for doing the reverse side. I may drill registration holes in that lip, but that is not my current issue.

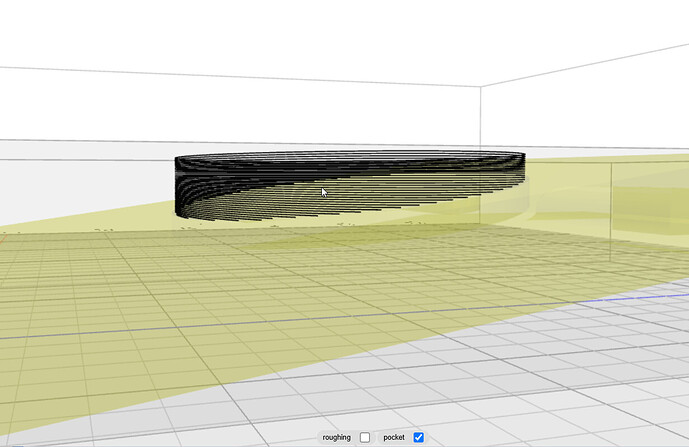

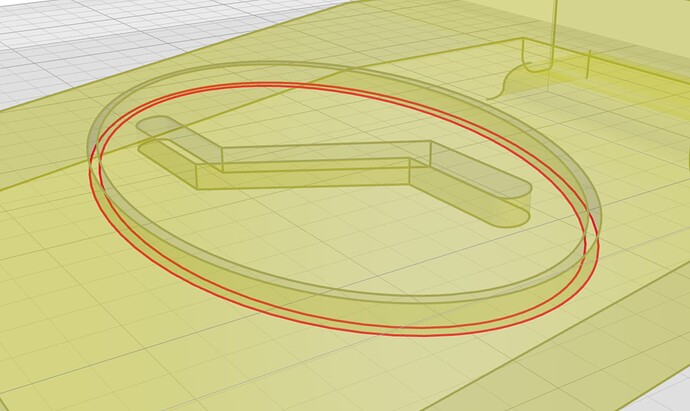

The roughing process is fine and I can use contour X & Y to get most of the way to where I want to be, but the logo engraving is challenging me. If I use Pocket then I run into a couple of issues: first, there is a lot of “machining air” going on as the process do not recognize that the majority of the material has already been removed, and; more importantly, I cannot get the elipse portion of the logo to actually cut into the new surface. It seems to come down to it, but does not penetrate it, while the central part of the logo does.

I have tried redefining the tool so show a longer cutting surface - no change. I have also tried splitting the pocket into two pockets - also no luck. I can provide the workspace upon request.

Any help would be appreciate.

I would use a Rough operation, remove all in Z, and leave 0.1-0.2mm stock. Then do a Trace for the cleaning up the edges.

Regarding the ellipse, how wide is it and what diameter tool?

Hi Matti. Thanks for the quick reply. We seem to be on the same page. I started with a rough leaving 0.2 stock. Then an X & Y contour to refine the surfaces.

The width of the ellipse channel is 1 mm and I set the pocket to use a 0.8 mm endmill.

Here is a link to the workspace file:

Try Trace instead of Contour. Select the lines/loops you want to trace, define if tool should follow in- or outside said line/loop. Contour is better for more curved shapes, imo. Unless you really want to touch off all surfaces ofc.

Pls share your workspace so it is easier to show how one would go at it. There is always more than one way to do it, and i really enjoy seeing how others solve the same problem.

edit: just saw the workspace. Thanks!

1 Like

Just looked at it real quick. I have to go to bed here any minute.

I didnt realize the surface with the ellipse is angled. That is probably why it didnt clear it. Try keeping that surface in perpendicular to Z.

Also, your 0,8mm end mill is just 3mm long, so it could not reach down even with that surface perpendicular to Z.

I can look more at it tomorrow, if no one else has solved it for you by then.

Thanks Matti. The surface that the logo is cut into is angled, but the center of the logo seems to work perfectly fine, and it mills the ellipse only up to the angled surface.

The 3mm length of the end mill would not be an issue since the bulk of the material is already gone.

Thanks for your help.

the next refactor of the trace op will allow it to follow non-planar paths. that will (eventually) make shapes like this easier.

1 Like

Hi Stewart. Does this mean that I cannot carve this shape currently?

You certainly can. I only meant that a future trace will make this more optimal. I notice that the oval outline is too deep for the selected tool. The shaft interferes at the boundary and that’s why the cut is limited by Kiri.

sgb-lid-top-alt.kmz (383.8 KB)

for your consideration. I’ve hacked the oval by abusing all parameters of a pocket operation. 3d trace would be the right way when it’s available (high on my list). I’ve also replaced the contour with a pocket + contour op. and I’ve lengthened the endmill flute so you can see how this would cut with the right tool.

LOL. I love these early days of learning a new process where every answer spawns a whole new set of questions.

- How did you “turn off” the two existing contours without deleting them?

- Previously the oval pocket started at the upper surface of the model. Now it starts at the upper limit of the oval itself. How?

- The depth of that pocket was always 2.5mm, so the 3mm flute should not have been an issue (though this is only true if considering the roughed surface as already gone).

- Replacing the “contour with a pocket+contour” does not allow for x+y refining… or am I missing something?

Don’t answer that last bit… I’m definitely “missing something” lol

I just implemented some of your suggestions. I don’t like using pocket_contour for the general surface as it produces a finished product that is not only coarser, but also does not match the desired shape. That said, using pocket-contour for the logo works great. I think the biggest difference there is that as soon as I enable the pocket’s contour option it is suddenly surface aware (for lack of a better term) - i.e. it does not try to create the pocket from the very top, but rather starts at the model’s sloped surface. This also negates the need to redefine the tool’s flute length.

I’m not sure I understand the -0.35 expand option, but it does help.

Thanks again.

Excellent! Thanks for taking the time to provide such a detailed response. VERY helpful. Have a great weekend.

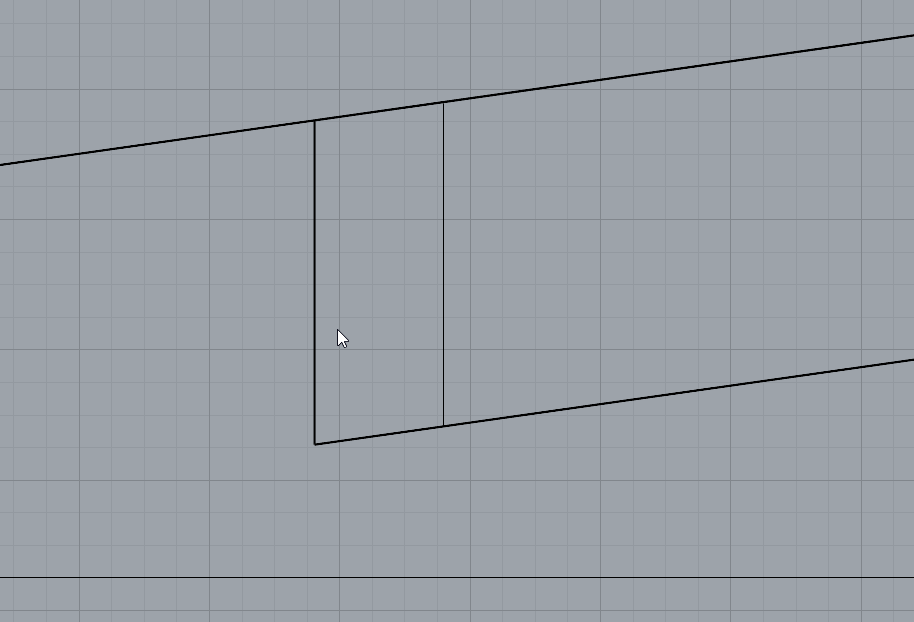

Hi again. I finally found the time (in mid-renovations) to try and cut this. It turns out that the hacks to the pocket-contour for the oval result in bit-breaking paths that plunge to nearly full depth. There is no “step down” increment with pocket-contour. So far I’m still not seeing a way to do this project using KM.

For reasons I do not understand, pocket-contour creates wildly fluctuating depths with no step-down option, and pocket without contour cuts exactly as expected but only down to the object surface and not at all into it. It DOES follow the surface, but does not cut into it.

the walls aren’t perfectly vertical and this isn’t the intended use case for pocket + contour. the contour lines come from following the facets on the mesh. so it looks crazy when you can’t see those (well, you can turn that view on). pocket + contour is intended for smooth surfaces curving in XYZ. we’re not able to use the original spline/nurb surfaces which would lead to more sensible paths.

however, the updated trace operation which will be in release 4.2 (tentatively slated for this weekend) might get you there.

I’m looking forward to that, but to be clear, the walls are completely vertical. The pocket was created using a 2.49mm vertical shift of the upper curves.

yep you’re right. the contour code tries to smooth the path between adjacent faces. so the triangles alternate hi/low but the computed centers aren’t aligned on the vertical face.

Thanks again Stewart. Given what you said about the smoothing algorithm I tried the pocket with a smoothing setting of zero - that worked perfectly.

1 Like