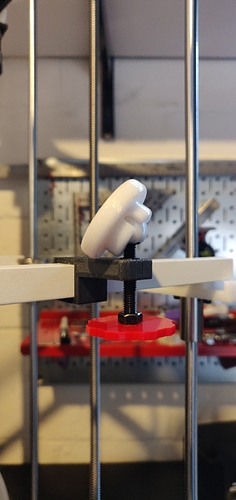

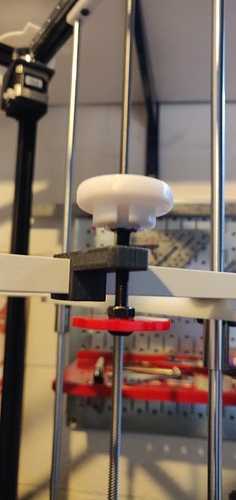

I built a little prototype of something that might work for me. I printed this in PTEG. The joint could be attached to the bed with 3M 468MP tape. The ball sits loosely in the joint and allows the bed to move as it gets hot and the screw to turn when I adjust it. But it will still hold the bed in place when I remove the spring steel build surface.