Major feature work is complete. The next week will be devoted to the ruthless hunting and killing of bugs. PLEASE help me in this task by hopping onto the dev release server and putting Kiri through its paces. A short summary of the work that went into this:

137 commits

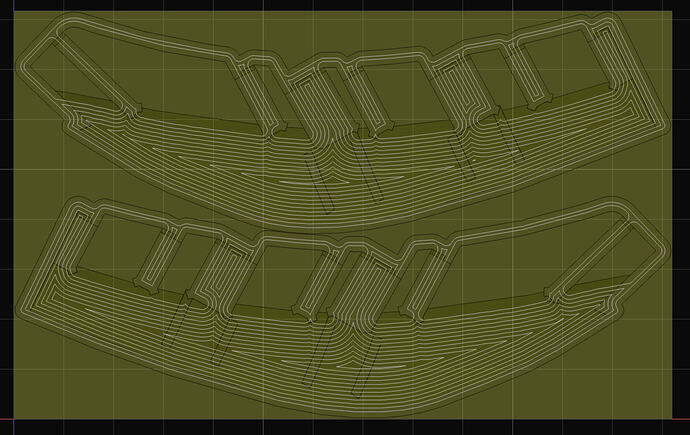

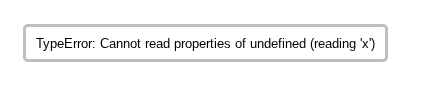

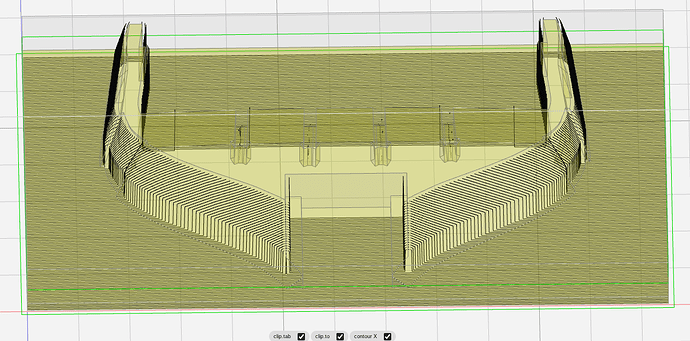

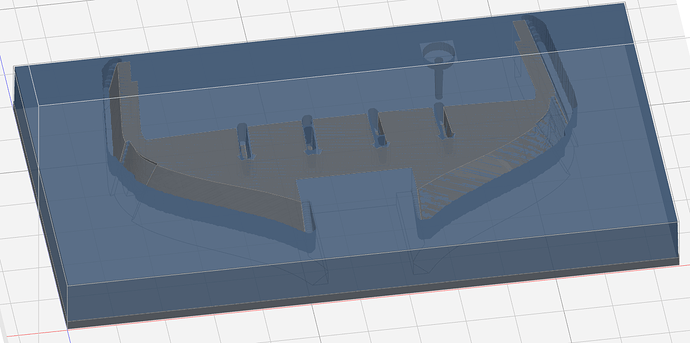

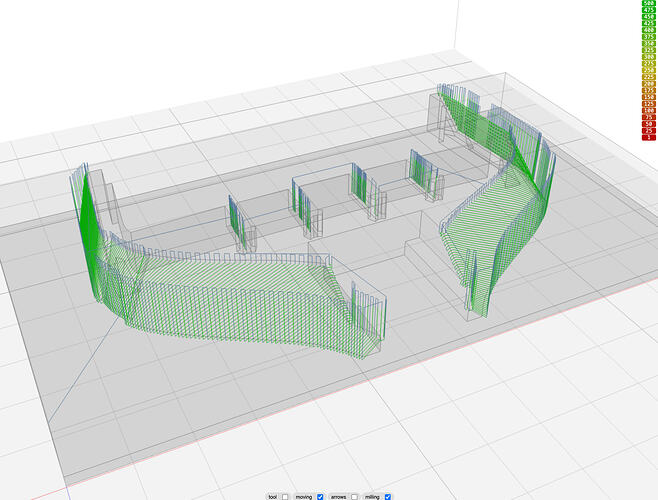

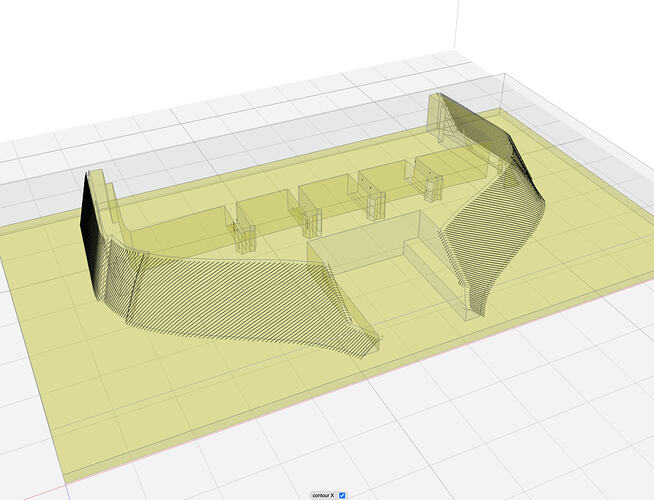

CAM Path Planning Refactor

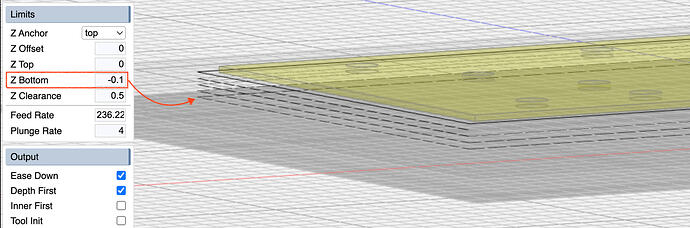

The routing and path generation system underwent a complete overhaul, enabling significantly improved collision detection, smoother universal ease-down moves, and better tool shadow analysis. This foundational work makes operations safer and more reliable, particularly for complex geometry. The refactor replaced zMax with zSafe throughout for clearer safety height semantics.

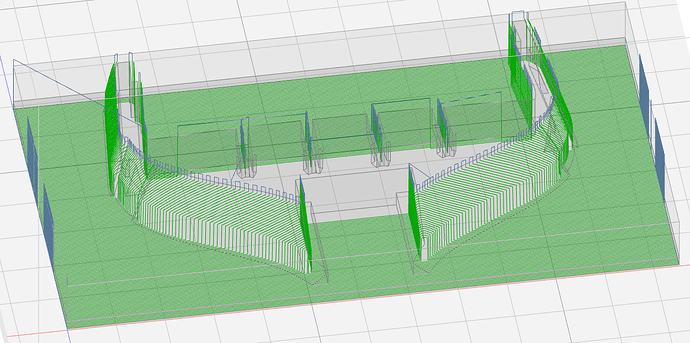

New “Area” Operation

A unified operation type that consolidates trace, clear, outline, and surface machining into one interface. Includes linear surface machining with constraint angles, and full tab support across all modes. This simplifies workflow by reducing the number of operations needed for complex parts.

Taper Ball Tool Support

Complete implementation including tool editor with visual preview, accurate profile generation for collision detection, and 3D animation support. Tapered ball nose endmills are now fully supported throughout the toolchain.

Enhanced Tab System

Tabs now properly integrate with travel boundaries, merge when overlapping, and work correctly with indexed rotary operations. Improved handling ensures tabs are respected during ease-down moves and thru-cuts.

4th Axis Improvements

G-code parsing now includes rotational interpolation for smooth A-axis visualization. Added manifold-based indexed animation for better accuracy and lathe axis reset macros.

Camera Controls

Runtime switching between orthographic and perspective projection with preserved zoom preferences and corrected aspect ratio handling.

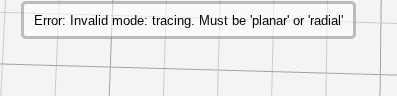

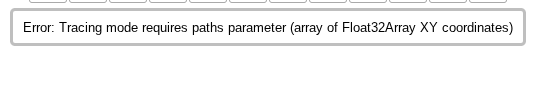

Roughing & Trace Operations

New flat passes option for horizontal roughing strategies. Inside/outside trace now supports open polylines with improved dogbone handling.

Technical Notes

The path planning refactor is the most significant change in this release, touching routing, pocketing, and safety moves throughout the CAM system. Users should test thoroughly with air cuts, particularly on complex indexed parts.