Looking for ways to manage carving around irregular objects: because my dimensional carves are deep, which makes finish carving problematic because the collett collides with the outside scrap areas if I don"t pre-design in a ramp outside the carve area during the modelling process.

“Outline” mode has potential, but does not have any more than 2 passes for the “wide cutout” setting, so my collett still collides with uncut scrap areas when using my shorter 1/8 or 1/16 bits for finishing passes around edges.

Would it be possible to add an editable number box in the “wide cutout” setting? Also, an offsett box, to manipulate the path origin to inside or out?

Or is there another way of accomplishing it in KiriMoto already?

Another tactic I have unsuccessfully employed to carve around outside edges is importing a SVG path. However it seems to group with my existing object, and I cannot place it properly. I had hoped it could be a simple path without fill that I could place around my 3d object carve. Wishful thinking… I know. But I love using Kiri:Moto anyway

Thanks

all things are possible with a little bit of coding…

editable wide cutout seems like a good option. importing SVG/2D paths just for following is on the TODO list. I like this option for lots of things (text). but it’s quite a bit more work…

I will be here, whenever youre ready. Thanks

Editable wide cutout would suffice though if its not too much trouble…

regarding “Also, an offset box, to manipulate the path origin to inside or out?” it would be better I think if it could be optionally in increments as well…? That way I can use it to specifically shave off an expendable amount around object edges. (since this is in the category of wishful thinking)

Though the ‘follow path’ option you are pursuing is the most ideal method, because I can outline the 3d object orthographic top view in Inkscape, etc. & smooth the path most easily there, to overcome the jagged edges resulting from raw outlines produced from the 3d model’s face edges.

Editable wide cutout would suffice, if thats easier to implement.

Thanks

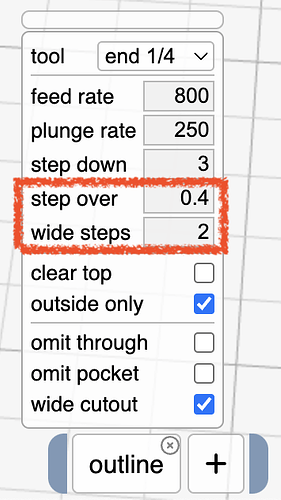

Ok, for your consideration, I have pushed the following change to dev.grid.space which adds the wide steps option when wide cutout is selected. you will want to disable the depth first output option.

Wow, that was FAST, thank you so MUCH!

P.S. - I am teaching classes on Blender 3d at my local library, in their Maker Space. I frequently suggest Kiri:Moto as the CAM for processing their 3D prints, not only because it is very competent, but the tech support is outstanding.

1 Like

The dev version did not work for me. I tried 2 different carves, unfortunately I processed other files after that, so I have no Workspace.kmz to share with you.

The 1st carve I needed a hole in the carve centre (depth first was not enabled) and had to stop the rough pass because the carve was ‘hammering’ like a drill operation in certain areas, but not others, while carrying out the roughing pass. When returning to the same areas, the ‘hammering’ would recommence. In the past, I have enabled this function when drilling, but during a rough pass it should not have done so.

The 2nd carve had no hole, but was deep so it needed a wide (4 pass) cutout. I had it setup to carve the wide cutout in the 2nd gcode file, after the rough pass, and prior to the finish pass.

The wide cutout pass appeared normal in the G-Sender software preview, but it only carved down depth of two passes out of 12, and just repeated the last instruction endlessly (I guess that, because after going around carving air a few times I aborted the process).

Wide cutout shows promise though! Just this dev version seems buggy?

I don’t understand “hammering”. The preview shows the paths in the gcode, so I can’t come up with a reason why it would do anything different from the visuals other than controller issues. Do you still have the gcode for these two things for examination?

I ran another gcode file with the dev version, I didnt want to burden you with looking at my gcode & likely finding nothing wrong- you would have been right.

The “hammering” I described was what I thought was “peck” drilling- it sounded just like it when that file ran.

It was actually occurring because the edges of my models are ragged, caused by deleting faces in 3D… each face is a tiny square, and the software was faithfully following those jagged lines, even on interior areas & early on in the carve. I aborted this as well, lest my cnc machine rattles loose like an old Harley after a long trip.

This was occurring in the roughing pass gcode file- meaning the problem had not been encountered yet, because the wide cutout op had not run yet.

In summary - the paths seem to be the best application for me, since I am assumung I will be able to smooth them somehow, with KiriMoto or Inkscape.

However I would use the outline wide feature on other models requiring stock clearing, just not ones without smooth edges - so I hope you will implement it when you are ready to do so.

Thanks

![]()