Hi,

I might have a setting wong or maybe I found a bug by accident.

While running a job, I noticed that the CNC was moving but cutting almost nothing. I expected a step down of about 3mm.

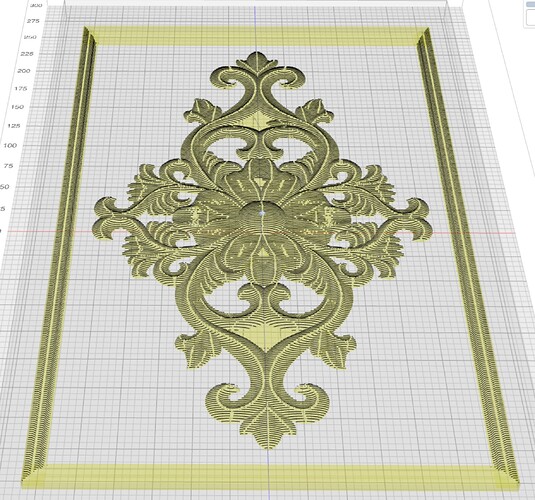

I then examined the file and found the following:

(I specifically looked at one area to try and find the issue)

25013 Z goes down to -4.8557

This is expected

25026 Z goes down to -7.1281

Also expected

Here comes the problem

55969 Z only goes down to -7.1729

73974 -7.2402

81867 -7.2626

89900 -7.8676

102830 -7.8676

I used Mach3 “Run from here” to skip ahead to around line 105300 and it ran perfectly from there, eliminating about 50 000 moves.

Do I have something wrong, or is this a bug?

Thank you

I tried uploading the workspace but it is too big.

I will email it to you.

Thank you

I won’t know until I see your model and settings, but if you’re using roughing with ‘clear faces’ and there are many Z aligned faces with close Z values, this can happen.

1 Like

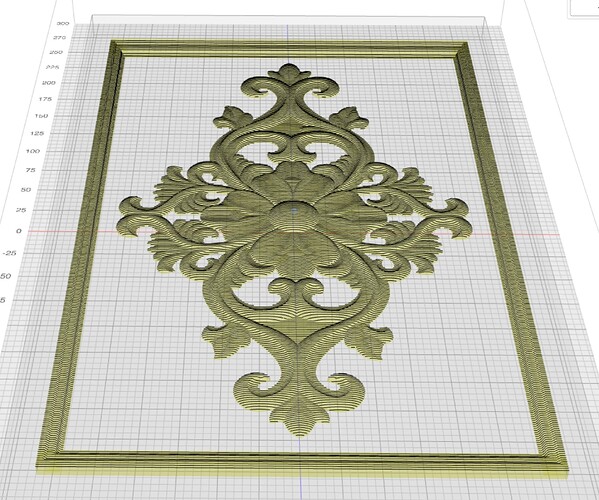

I have a question. First, though, you should disable “clear faces” and enable “clear top”. Second, why are you using “curves only” for contouring when the object is organic? There really aren’t flat spots, so contouring the entire piece will be faster and more reliable without and false flat spots detected which results in a lot of Z raises. Side by side images and link to updated workspace attached. Letting contour handle the whole surface relieves roughing of needing to care about flat spots (if they exist).

updated workspace

Hi Stewart,

I have no real reason except that I interpreted the function wrong.

I will follow your advice.

Much appreciated.

Thank you

1 Like