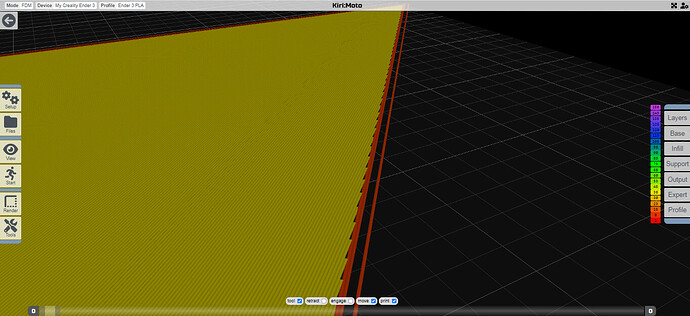

Hi. I have a CAD design that I am trying to slice with kiri:moto.

My design has a long diagonal and the slice attempts to tackle this diagonal on a bias that isn’t working; the gaps produced at the end of the toolpath are causing adhesion issues.

Ideally, I could get the slicer to adjust its diagonal to match with the angle of my part, but I can’t seem to get it to do that. That position needs to stay fixed for this print. Are there any settings that would allow me to adjust the pathing angle that the slicer chooses to attack this diagonal in Layer 0?

More specific detail on the trouble: At the end of each of those diagonal toolpaths, the head goes spastic; it terminates the line, moves inboard, down, out, then over to the end of the next line.

On the bottom of these toolpaths, I get nice and smooth boustrophedon pathing. But out here on the tails of these diagonals, the moves are ridiculous and I don’t know what settings (if any) are in my control to rectify this issue.

Can you right-click export workspace and DM or email the .kmz to me for analysys? [ sa at grid dot space ]

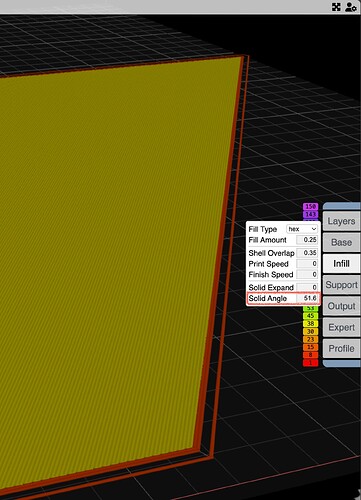

I played with your model, and setting the infill starting angle to 51.6 causes the infill to align to the long edge

Oh, sweet! Thanks a ton for that. I had never even tinkered with that setting. I’ll have to remember that one. On the topic of settings, what is the distinction between the Layer height in the Layers category and the Layer height in the Base category?

base is first layer settings for normal 3d printers and for belt printers, any extrusion touching the belt.