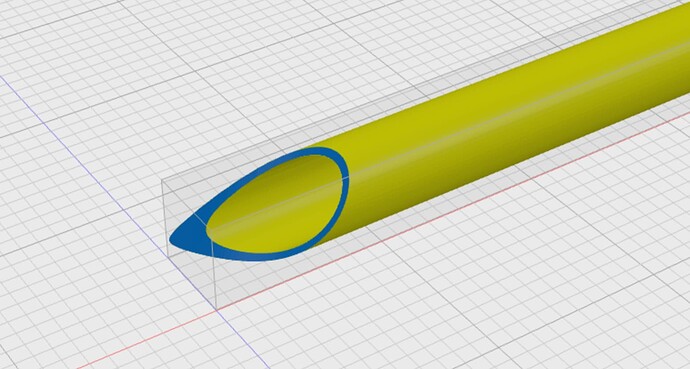

not getting best way to cope end of tube or even just do partial machining of any stock (machine just one side) seem like the tool path wants to machine out the whole item not just the path desired.

workspace (5).kmz (223.9 KB)

yes just the end of the tube…called a cope where one tube mates with another

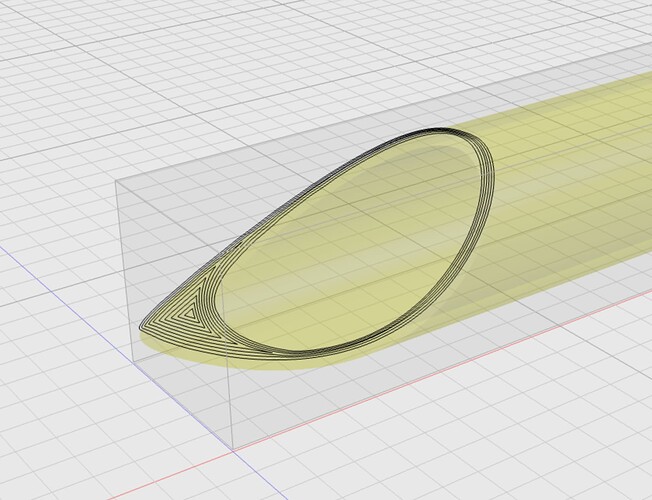

it’s a really fine detail. not sure I have a good answer for that right now. but i’ll play with it.

a ball endmill or if I rotate it square the side of the cutting tool with a normal endmill will handle it close enough however I do not know how to isolate only the path I want

do you want to do a roughing pass but constrained to the end? or something like this?

tube-end-cut.kmz (1.2 MB)

that would be great yes

I loaded your file and the g code output or animation are not working

G21

G90

M30

is that a trick or software switch somewhere

I now am getting something when selecting the face…sorry about my ignorance

will get back to you

works …Thank you I have lots to learn

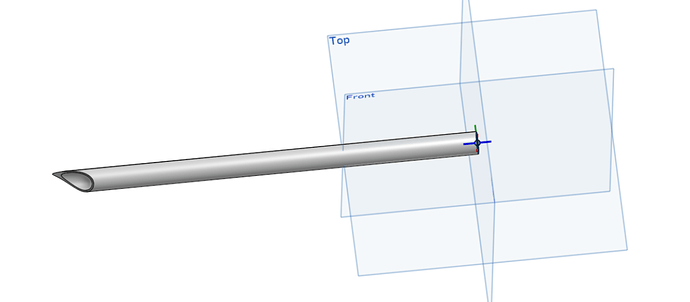

I tried to cut this today and although the animation and my control showed the proper tool path the machine cut the item in the original orientation of the Onshape position…so it appears that the rotation option in Kiri did not fully work in x rotation… screen shot of original Onshape and kmz and nc files

workspace (10).kmz (171.8 KB)

cnc-020.nc (190.8 KB)

the animation disagreed with the final cut on the cnc? did you use a tool that matched what you setup in Kiri?

the file I send shows 1/8 end mill which is what I used…the original in onshape was rotated 90 after loaded in Kiri …it showed correct in the rotated Kiri anamation but cut in the original 90 degree position from onshape…not sure I am making fully sense but I will rotate the part in onshape to be parallel with the top plane and see if it takes care of the problem if that works then it certainly is an easy fix on my end

I think I might have had my zero in the wrong place at corner of stock rather than the center of the cut…duh

that was it but still had a problem in that I would have preferred the tool start at the top rather than plunging to the bottom of the tube…is there a software setting I can hit to for that

I think offset of the zero to the top of the cut may have solved that issue

where as the cutter does start at the top of the tube as it moves toward the cutter path at the bottom of the tube it plunges down so that I am cutting almost full depth…where as it would be better if I had only .01 thousand step down…is there a way to do that or do I have to trick the software with an aux part

workspace_cope.kmz (569.4 KB)

Add a roughing pass. Ignore all my numbers. I dont understand imperial in this context, so i just put sthing in there.