I’m very excited about this new CAM feature. As I say in the video, this is the most complex new feature I’ve put out there in years. There’s a lot remaining to complete the functionality (and kill bugs). But it’s also very powerful as is. I look forward to your feedback.

Great new feature!! Thank you for your hard work.

I am not sure if its a bug, but I can’t get my parts to lay flat on top of the grid when I control click a flat surface.

Update: I found out why this was happening. It had to do with the stock and limit parameters. I believe the part to be milled should lay flat on the grid independent of the stock. Then, use the limits to position the part inside the stock.

Nice! Your implementation looks way more flexible than anything I would have come up with.

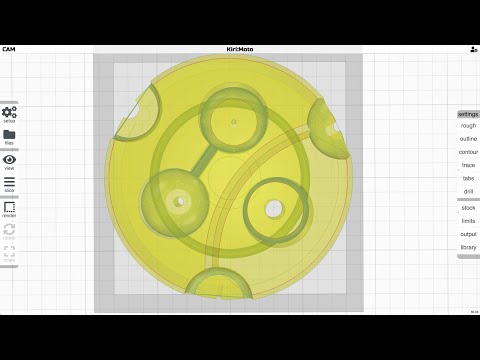

Unfortunately I haven’t had any success with it yet. The part I was using to test was posted in the “2.4 Roadmap and Updates” thread. Basically a curved surface with curved slots. After analyzing, I only get a red box outlining the base of the entire part. Nothing shows up when I hover over the slots themselves. I made a extra small tool just to be sure the tool size wasn’t a problem.

Let me know if there is anything I can do to help troubleshoot.

The other issue I can see is that there are a bunch of slots and individually selecting them will be tricky. Some kind of “select all” would be handy.

slots curved in Z-space aren’t supported at the moment, only features coplanar with Z. identifying those features is next-level. but it is on my roadmap.

Ah, that makes sense. I am sure sure curved surfaces make things non-trivial.

EDIT: I have also been working on my own G-code generator for the curved slots, so I will probably have an alternative for this functionality shortly. Consider my use case as a best effort feature request.

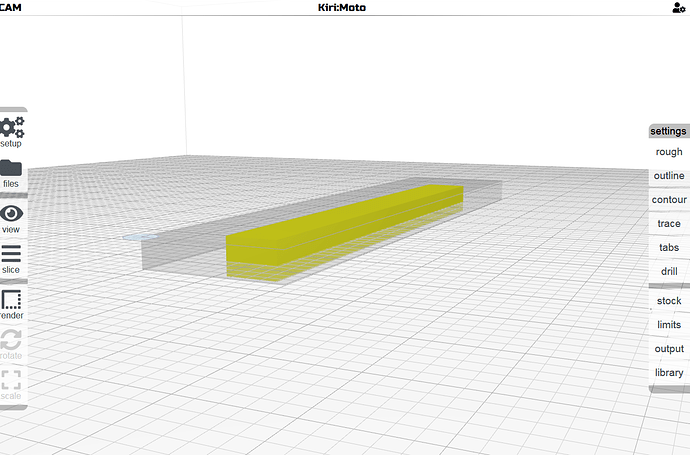

is this a standalone parametric tool?

Yes, you put the parameters of the part in a config file, run the script, and it spits out the G-code to carve the part. No CAD/CAM at all. Unfortunately, it isn’t as trivial as I had hoped to create those curved surfaces and curved slots from scratch!

One perk of writing G-code from scratch is it can be highly optimized. The script spits out typically a few kB of G-code vs. typically a few MB generated from 3D modeling.