A: While roughing the two long parts, the mill steps down 2 times as expected. Then it does an “empty” cycle. What can I do to prevent that. Its not really a problem about wasted time. Its more about cycling though a slot and wearing the bit.

B: When it started to cut the pockets I’ve got different feed rates. It turned out that the actual feed rate was 200 or 250 mm/minute. But it should be 500 mm/minute. Any idea, what went wrong?

Feed_and emptyCycle.kmz (234.7 KB)

When I preview, which “slice” # shows the empty cycle? I’m looking into a couple of feed rate anomalies. Is there a simpler repro case?

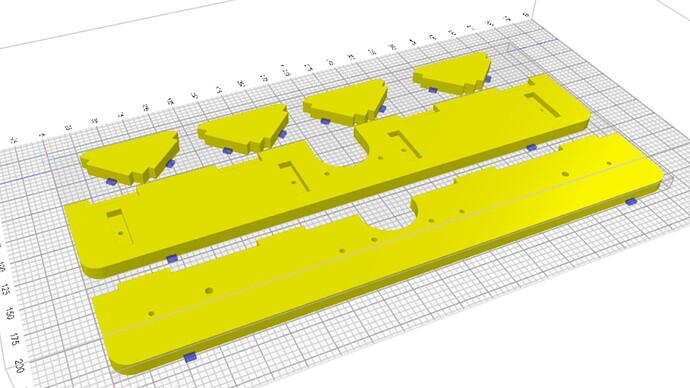

I removed some parts:

Empty_Cycle.kmz (242.6 KB)

The “almost” empty cycle is now on slice #44. In the gcode it jumps from

631: G1 Z-5.9900 F200

to

701: G1 Z-6.0050 F200

That is caused by the use of the clear faces option which creates extra passes on flat surface during roughing. In this case, the face is nearly coincident with an existing pass, so it looks like extra work. I would recommend disabling that option and using a “pocket” operation instead to clear those flat areas.

1 Like

OK, got it. Thanks for your reply.

How about the feedrates?

I recently added code that attempts to detect / slow the first roughing cut that’s fully engaged (not a step over) so that the chip rate was roughly equivalent. It’s not perfect. More of a proof of concept.

1 Like