What would be the best milling operations and tool type for this model to get clear crisp edges and sharp corners? The recesses will be 6.5mm and I ran test material with just a roughing operation using an 1/8" shank 2.5mm bit that came out ok but wondering how I can get the corners more sharp & square? Using a smaller diameter cutting edge seem like it would do the trick for the outline, but doesn’t seem like it would be efficient for clearing the rest of the material inside the blocks.

Is there an operation that can precede the roughing with a smaller bit followed by roughing with a larger one?

Thanks for your help.

Jay

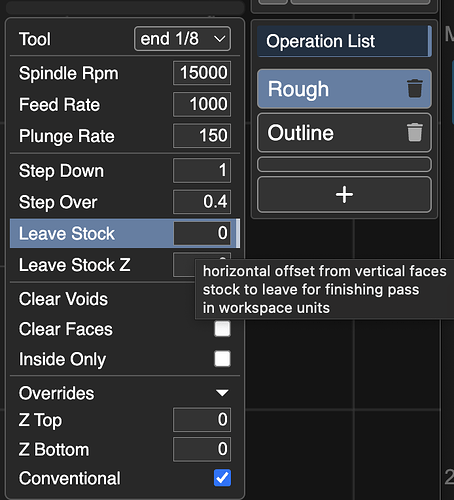

you typically start with roughing using a larger tool to clear most of the material quickly. you can “leave stock” in the roughing operation that can can be cleared by your final outline pass with a smaller tool.

Thanks Stewart, so with the the roughing operation are you able instruct how much or a certain distance to leave out? Then would it be a separate g-code to for the outline operation so that you can change tools in between?

yes. and the export function supports .zip output that separates each operation into its own file for situations when a cnc machine doesn’t have an auto tool changer.

you can also toggle conventional to change the cutting direction which might work better depending on the geometry of your tool (up cut, down cut, or compression)