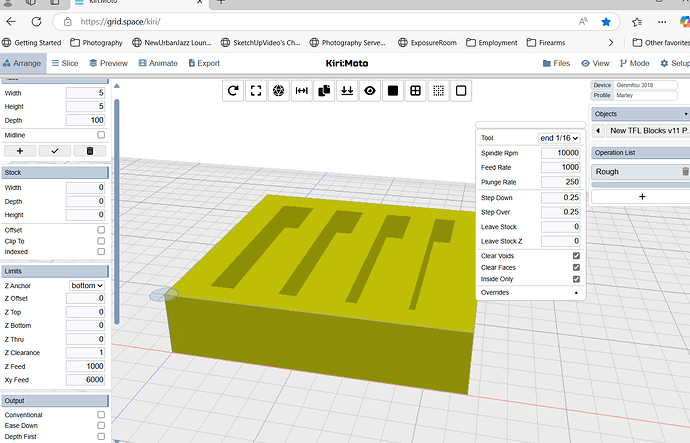

I thought I had my settings down for roughing this wooden part as I had milled the male portion of the model (a denser wood) with no issues, but using the same setting for this part on the initial cut the spindle speed decreases and the bit binds up and breaks. Im using Candle to run the gcode on a Gemnitsu Prover 3018. It seems also that i have to manually set the spindle speed in Candle and power it on prior to running, but it still slows it down wen sent.

If I read that right 1/4 inch step down on a 3018 would be a bit too much step down. Try taking a less aggressive cut.

The 3018 is not a very rigid machine and the spindle is prone to flexing and binding. I would suggest a slower feed rate and a smaller step down for such a small end mill.

According to the 3018 docs, spindle speed can only be set manually.

Understood I’ll try that. If I’m working in mm units, won’t the step down value also be in mm? What is happening with the machine is that the initial feed rate is slowed (for unknown reasons) to around 2000 until about the 7th or 8th pass then it gets up to what is supposedly 10000.

Thank you

Is it only slower when cutting? If so, that would indicate that you’re asking it to remove too much material or running too fast. If it then speed up at the bottom, it could be because the last cut is removing less material, which could be the case when you have “clear faces” selected.

It’s only slowed on the initial several cutting passes of one of the first recesses, then while cutting the spindle just increases speed up to the set value.

I do not believe gcode can control the spindle speed of this machine. therefore it must be related to the cutting conditions (depth and rate of material removal)