If I attached a laser diode to my router spindle mount after I engraved a terrain, any ideas on how I would then apply an SVG( topo lines, etc ) over the milled model? Diode lasers need a pretty tight focus given their limited power.

Cool idea.

There biggest challenge is moving the Z axis to keep the laser focused. I can’t think of a way to do this without writing some code. However, Kiri already has the ability to parse some SVGs and turn them into paths. So it’s a simple matter of finding the Z height at each point on the path once the path is registered to the part.

This may fall into a more general class utility for importing SVGs and overlaying them onto parts to generate part-aware milling operations. Can you think of use cases other than laser that would benefit from this?

another idea I had was to use the laser to impart fake grain into MDF signs by milling the sign and then laser engraving a wood texture over it. But that’s another laser use case.

I think to be convincing, it would require changing the laser power along the paths

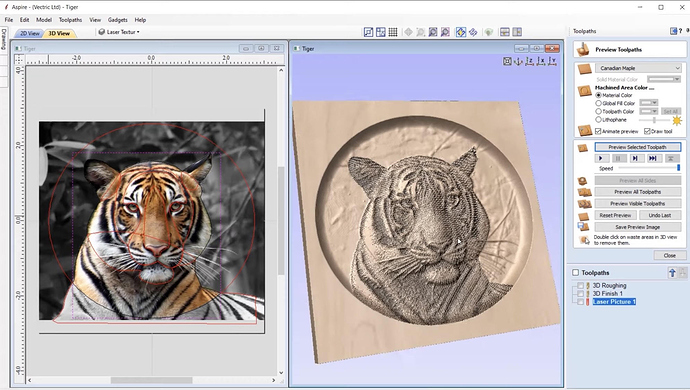

true, just doing lines won’t have the wow factor. A friend I just asked about this showed me that VCarve recently added this since they now sell a laser module to add to their machines( $1000 ) add-on.

I’m going to look into doing imported 2D overlays on a 3D terrain

the video I found introducing the carve/laser module for Aspire software was quite limiting. It looks to only have the ability to make a 3D bumpmap from a black/white image and then apply the laser data based on the original B/W image. I don’t run VCarve nor Aspire but from what I’ve heard from others is they use it for their project design with very little 3D capability. A number of people I know go with Fusion 360 for 3D design and then rely on its toolpath generation.

My workflow tends to go with using tools optimized for their purpose like CAD for creating the 3D model and a slicer/toolpath generator which takes in the model. Even for the laser I will often do the design in Inkscape and then import into LightBurn as opposed to doing everything in LightBurn. I believe there’s more power in the separate tool approach.