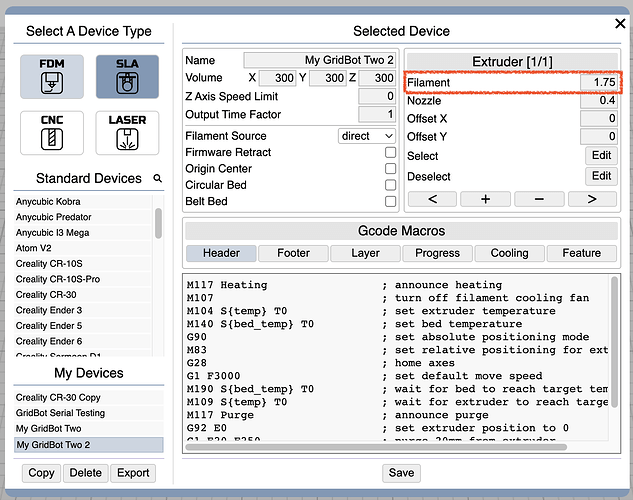

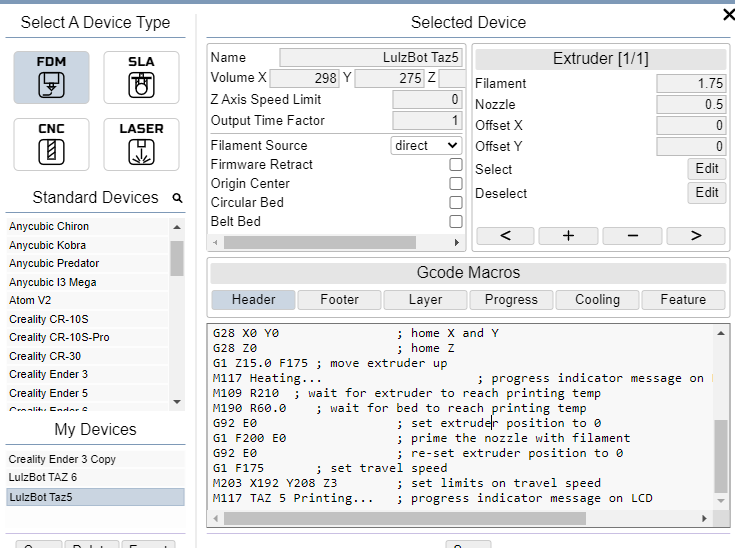

I am having some kind of overextrusion problem with a taz 5 printer. 0.5 nozzle and using 1.75mm filament. I imagine the problem lies somewhere in the fact that I use both 3mm and 1.75mm filament. Below is the header code and g code of what I am trying to print. One of the comments is “Filament used: 0.293389m” this is because i took the header code form CURALE - I am pretty sure my kirimoto settings are different - but I just can’t tell in the gcode where it would be denoting filament diameter.

Header:

;Generated by Cura LulzBot Edition GCodeWriter Version: 3.6.37

;FLAVOR:Marlin

;TIME:989

;Filament used: 0.293389m

;Layer height: 0.14

;Generated with Cura_SteamEngine 3.6.37-win10

M82 ;absolute extrusion mode

;This G-Code has been generated specifically for the LulzBot TAZ 5 with standard extruder

M75 ; start GLCD timer

M140 S60.0 ; start bed heating up

G90 ; absolute positioning

M107 ; disable fans

M82 ; set extruder to absolute mode

G28 X0 Y0 ; home X and Y

G28 Z0 ; home Z

G1 Z15.0 F175 ; move extruder up

M117 Heating… ; progress indicator message on LCD

M109 R210 ; wait for extruder to reach printing temp

M190 R60.0 ; wait for bed to reach printing temp

G92 E0 ; set extruder position to 0

G1 F200 E0 ; prime the nozzle with filament

G92 E0 ; re-set extruder position to 0

G1 F175 ; set travel speed

M203 X192 Y208 Z3 ; set limits on travel speed

M117 TAZ 5 Printing… ; progress indicator message on LCD

** Partial Gcode from KM**

; Generated by Kiri:Moto 3.9.1

; Tue Apr 11 2023 07:51:10 GMT-0400 (Eastern Daylight Time)

; Bed left:0 right:298 top:275 bottom:0

; Bed type: fixed

; Target: LulzBot Taz5

; — process —

; processName = Taz 5 .3 height

; sliceHeight = 0.3

; sliceShells = 3

; sliceShellOrder = in-out

; sliceLayerStart = last

; sliceFillAngle = 45

; sliceFillOverlap = 0.3

; sliceFillSparse = 0.25

; sliceFillRate = 0

; sliceFillType = hex

; sliceSupportDensity = 0.25

; sliceSupportOffset = 1

; sliceSupportGap = 1

; sliceSupportSize = 5

; sliceSupportArea = 0.1

; sliceSupportExtra = 0

; sliceSupportAngle = 50

; sliceSupportNozzle = 0

; sliceSupportEnable = false

; sliceSolidMinArea = 1

; sliceBottomLayers = 3

; sliceTopLayers = 3

; firstSliceHeight = 0.3

; firstLayerRate = 30

; firstLayerFillRate = 35

; firstLayerPrintMult = 1

; firstLayerLineMult = 1

; firstLayerYOffset = 0

; firstLayerNozzleTemp = 208

; firstLayerBedTemp = 56

; firstLayerBrim = 0

; firstLayerBrimTrig = 0

; firstLayerBeltLead = 3

; outputRaft = false

; outputRaftSpacing = 0.2

; outputTemp = 208

; outputBedTemp = 56

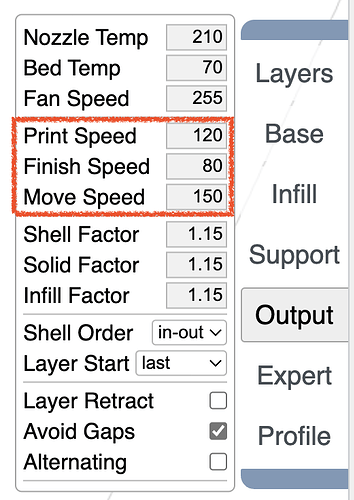

; outputFeedrate = 50

; outputFinishrate = 50

; outputSeekrate = 80

; outputShellMult = 1.25

; outputFillMult = 1.25

; outputSparseMult = 1.25

; outputRetractDist = 1.1

; outputRetractSpeed = 30

; outputRetractDwell = 20

; outputBrimCount = 2

; outputBrimOffset = 2

; outputShortPoly = 100

; outputMinSpeed = 10

; outputCoastDist = 0

; outputLayerRetract = false

; outputOriginCenter = false

; outputInvertX = false

; outputInvertY = false

; sliceMinHeight = 0

; sliceAdaptive = false

; zHopDistance = 0.2

; antiBacklash = 1

; sliceFillWidth = 1

; firstLayerFanSpeed = 0

; outputFanSpeed = 255

; outputRetractWipe = 0

; outputPurgeTower = 0

; arcTolerance = 0

; ranges = []

; sliceLineWidth = 0

; sliceFillRepeat = 1

; sliceSupportSpan = 5

; sliceSupportOutline = true

; firstLayerBrimIn = 0

; firstLayerBrimGap = 0

; firstLayerBeltBump = 0

; firstLayerFlatten = 0

; outputDraftShield = false

; outputBeltFirst = false

; outputAvoidGaps = true

; outputLoops = 0

; sliceFillGrow = 0

; sliceSolidRate = 0

; outputAlternating = false

; sliceDetectThin = off

; sliceLayerStartX = 0

; sliceLayerStartY = 0

; sliceSupportGrow = 0

; — startup —

;Generated by Cura LulzBot Edition GCodeWriter Version: 3.6.37

;FLAVOR:Marlin

;TIME:989

;Filament used: 0.293389m

;Layer height: 0.14

;Generated with Cura_SteamEngine 3.6.37-win10

M82 ;absolute extrusion mode

;This G-Code has been generated specifically for the LulzBot TAZ 5 with standard extruder

M75 ; start GLCD timer

M140 S60.0 ; start bed heating up

G90 ; absolute positioning

M107 ; disable fans

M82 ; set extruder to absolute mode

G28 X0 Y0 ; home X and Y

G28 Z0 ; home Z

G1 Z15.0 F175 ; move extruder up

M117 Heating… ; progress indicator message on LCD

M109 R210 ; wait for extruder to reach printing temp

M190 R60.0 ; wait for bed to reach printing temp

G92 E0 ; set extruder position to 0

G1 F200 E0 ; prime the nozzle with filament

G92 E0 ; re-set extruder position to 0

G1 F175 ; set travel speed

M203 X192 Y208 Z3 ; set limits on travel speed

M117 TAZ 5 Printing… ; progress indicator message on LCD

G1 E-1.1000 F1800 ; e-retract 1.1

;; — layer 0 (0.300 @ 0.3) —

M106 S0

G1 Z0.3000 F4800

; feature brim

G1 X146.3682 Y161.6600

G1 E0.0000 F1800 ; e-engage 1.1

G4 P20

G1 X146.3643 E0.0002

G1 X146.3653 Y105.3770 E3.4461

G1 X142.3766 Y105.3712 E3.6903

G1 X142.0184 Y105.3363 E3.7124

G1 X141.8052 Y105.2716 E3.7260

G1 X141.5607 Y105.1413 E3.7430

G1 X141.3183 Y104.8951 E3.7641

G1 X141.1685 Y104.6148 E3.7836

G1 X141.0865 Y104.2190 E3.8083

G1 X141.1698 Y103.8256 E3.8330

G1 X141.3199 Y103.5442 E3.8525

G1 X141.5960 Y103.2681 E3.8764

G1 X141.9642 Y103.1113 E3.9009

G1 X142.3848 Y103.0709 E3.9268

G1 X146.3653 Y103.0711 E4.1705

G1 Y92.3720 E4.8255

G1 X142.3756 Y92.3691 E5.0698

G1 X142.0203 Y92.3345 E5.0916

G1 X141.8068 Y92.2695 E5.1053

G1 X141.5668 Y92.1414 E5.1220

G1 X141.3196 Y91.8953 E5.1433

G1 X141.1905 Y91.6531 E5.1601

G1 X141.1250 Y91.4380 E5.1739

G1 X141.0983 Y91.1672 E5.1905

G1 X141.1670 Y90.8275 E5.2118

G1 X141.2959 Y90.5864 E5.2285

G1 X141.4722 Y90.3714 E5.2455

G1 X141.7610 Y90.1818 E5.2667

G1 X142.0217 Y90.1027 E5.2834

G1 X142.3797 Y90.0670 E5.3054

G1 X146.3653 E5.5494

G1 Y81.9710 E6.0451

G1 X129.0374 E7.1060

G1 X127.4308 Y82.1299 E7.2048

G1 X125.6917 Y82.6569 E7.3161

G1 X124.0890 Y83.5139 E7.4273

G1 X122.6857 Y84.6667 E7.5385

G1 X121.5315 Y86.0702 E7.6498

G1 X120.6761 Y87.6727 E7.7610

G1 X120.1477 Y89.4118 E7.8723

G1 X119.9900 Y91.0195 E7.9712

G1 Y131.0859 E10.4242

G1 X120.1467 Y132.6786 E10.5222

G1 X120.6739 Y134.4183 E10.6335

G1 X121.5308 Y136.0209 E10.7448

G1 X122.8526 Y137.6300 E10.8723

G1 X121.5308 Y139.2390 E10.9998

G1 X120.6739 Y140.8417 E11.1110

G1 X120.1467 Y142.5814 E11.2223

G1 X119.9900 Y144.1741 E11.3203

G1 Y166.6400 E12.6958

G1 X119.9930 E12.6960

G1 Y184.1105 E13.7656

G1 X120.1506 Y185.7175 E13.8644

G1 X120.6779 Y187.4561 E13.9757

G1 X121.5348 Y189.0602 E14.0870

G1 X122.6882 Y190.4628 E14.1982

G1 X124.0908 Y191.6162 E14.3094

G1 X125.6952 Y192.4733 E14.4207

G1 X127.4336 Y193.0000 E14.5319

G1 X129.0392 Y193.1590 E14.6307

G1 X146.3682 E15.6917

G1 Y185.0630 E16.1874

G1 X142.3817 E16.4314

G1 X142.0237 Y185.0273 E16.4535

G1 X141.8081 Y184.9619 E16.4673

G1 X141.5654 Y184.8324 E16.4841

G1 X141.3210 Y184.5867 E16.5053

G1 X141.1929 Y184.3472 E16.5219

G1 X141.1283 Y184.1341 E16.5356

G1 X141.1063 Y183.9115 E16.5493

G1 X141.1281 Y183.6903 E16.5629

G1 X141.1934 Y183.4751 E16.5767

G1 X141.3251 Y183.2282 E16.5938

G1 X141.5751 Y182.9863 E16.6151

G1 X141.8109 Y182.8599 E16.6315

G1 X142.0221 Y182.7955 E16.6450

G1 X142.3783 Y182.7609 E16.6669

G1 X146.3682 Y182.7580 E16.9112

G1 Y172.0600 E17.5662

G1 X142.3792 E17.8104

G1 X142.0239 Y172.0250 E17.8322

G1 X141.8095 Y171.9597 E17.8460

G1 X141.6108 Y171.8535 E17.8598

G1 X141.3965 Y171.6780 E17.8767

G1 X141.2067 Y171.3889 E17.8979

G1 X141.1134 Y171.0813 E17.9176

G1 X141.1139 Y170.7340 E17.9388

G1 X141.1932 Y170.4730 E17.9555

G1 X141.3220 Y170.2316 E17.9723

G1 X141.5665 Y169.9871 E17.9935

G1 X141.8082 Y169.8580 E18.0102

G1 X142.0205 Y169.7937 E18.0238

G1 X142.3792 Y169.7588 E18.0459

G1 X146.3682 Y169.7530 E18.2901

G1 Y161.6600 E18.7856

G1 X145.8682 Y162.1600 F4800

G1 X145.8643 E18.7858 F1800

G1 X145.8653 Y105.8763 E22.2318

G1 X142.3519 Y105.8712 E22.4469

G1 X141.9207 Y105.8292 E22.4734

G1 X141.6131 Y105.7358 E22.4931

G1 X141.2581 Y105.5465 E22.5177

G1 X140.9114 Y105.1944 E22.5480

G1 X140.6936 Y104.7869 E22.5763

G1 X140.5756 Y104.2179 E22.6118

G1 X140.6953 Y103.6528 E22.6472

G1 X140.9138 Y103.2432 E22.6756

G1 X141.3110 Y102.8460 E22.7100

G1 X141.8395 Y102.6209 E22.7452

G1 X142.3609 Y102.5709 E22.7773

G1 X145.8653 Y102.5711 E22.9918

G1 Y92.8716 E23.5857

G1 X142.3511 Y92.8691 E23.8008

G1 X141.9223 Y92.8273 E23.8272

G1 X141.6145 Y92.7336 E23.8469

G1 X141.2663 Y92.5478 E23.8711

G1 X140.9136 Y92.1967 E23.9015

G1 X140.7264 Y91.8454 E23.9259

G1 X140.6322 Y91.5363 E23.9457

G1 X140.5933 Y91.1416 E23.9700

G1 X140.6915 Y90.6565 E24.0003

G1 X140.8781 Y90.3074 E24.0245

G1 X141.1339 Y89.9953 E24.0492

G1 X141.5469 Y89.7242 E24.0794

G1 X141.9234 Y89.6100 E24.1035

G1 X142.3548 Y89.5670 E24.1301

G1 X145.8653 E24.3450

G1 Y82.4710 E24.7795

G1 X129.0620 E25.8082