I’m trying to create a metal letter stamp, so I want to leave the letter untouched and mill out all the surrounding metal, but leave a block of metal underneath.

In order to do this, my plan is to first do an outline with a small bit so that I can get all the fine details of the letter correct, and then continue with a pocket on the surrounding areas with a bigger bit to save a lot of time.

I’ve been doing a lot of research on how to approach this in KM, because almost all examples are of designs being milled out themselves, instead of an inverted milling operation like this. So far, I’m not sure if I’m missing something, but I’m stuck trying to get this to work, so I would like to ask the experts here!

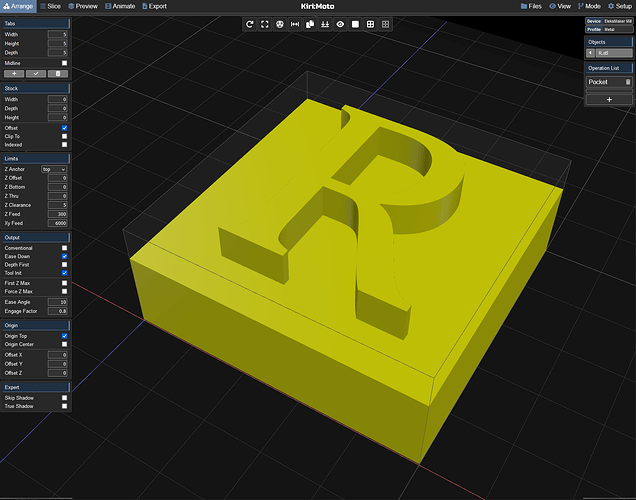

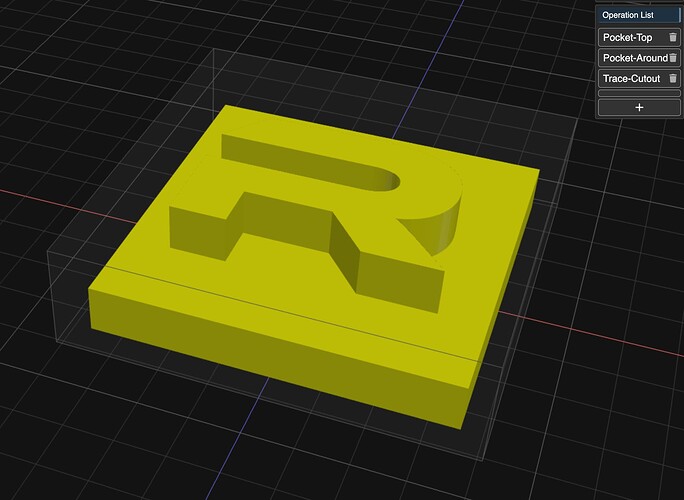

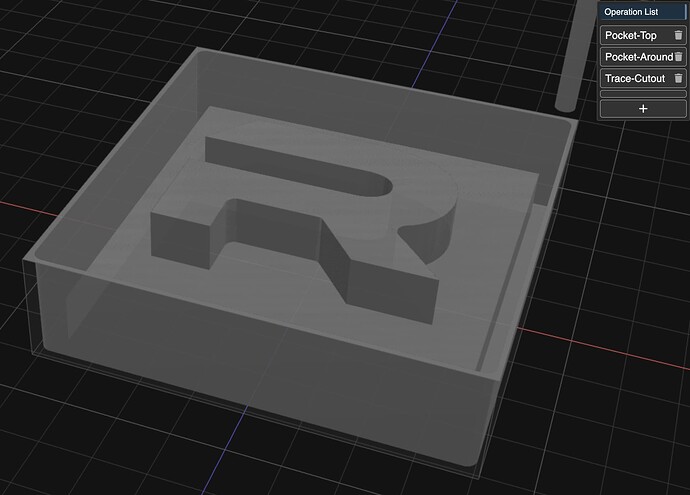

I created an STL where the letter rests on a block, because it seems like the pocket operation needs actual design surfaces to indicate where to mill to (which makes sense). This works fine for the second step of the operation, because with a negative expand I can perfectly indicate that the bigger bit should mill out everything, but skip the first pass that should be done with the smaller bit.

But with this block STL the outline operation cannot work, because the whole block is seen as the outline. I also have an STL with just the letter R, which of course makes the outline work, but now the pocket operation is no longer possible because I cannot indicate where to mill the surrounding metal to.

Ideally I would like to do this in one single job for the machine, because I’m afraid that if I create two separate gcode files with different STLs as their basis, it will create some small offset or something.

Because I can only embed a single image, I’ve included an example of the block STL. The single R STL looks the same without the block underneath. If needed, I can also upload the workspaces themselves. Thank you so much for taking the time to read all of this, and trying to help me get this working, I really appreciate it!