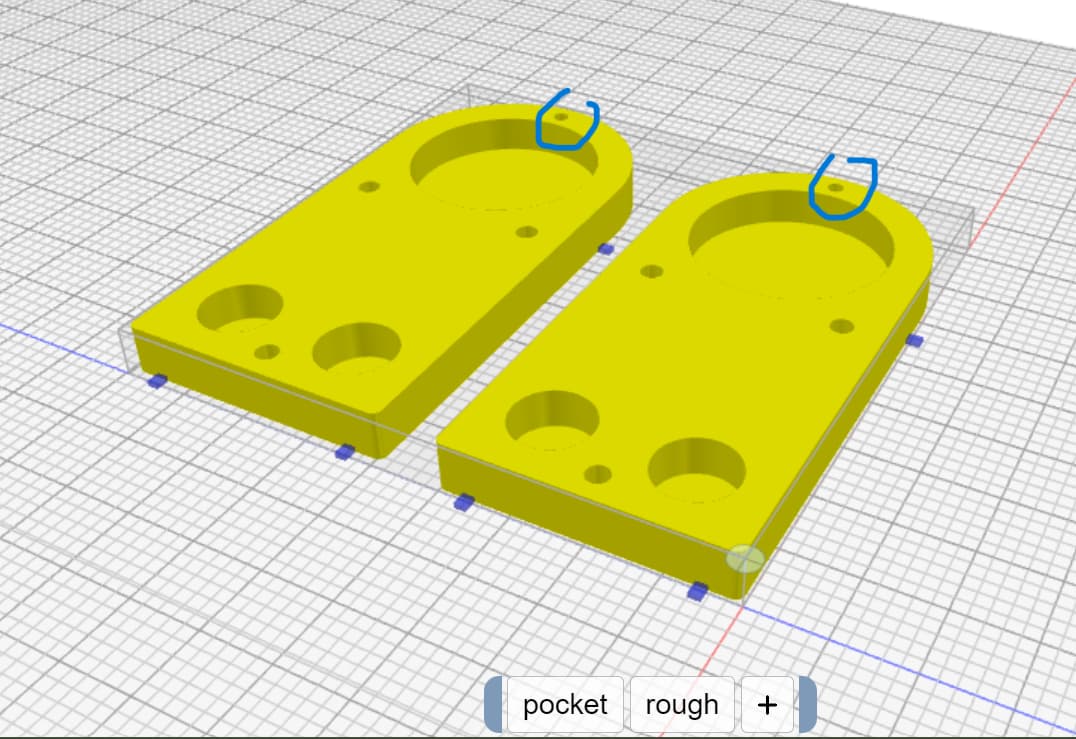

All milling paths are covered with a “rough” operation. Only the hole marked in blue is done by a pocket operation. From my point of view, the pockets should be milled before the rest. But this is how it is done:

- Left Part:

- Pocket

- Tool change

- Rough

- Tool change

- Right Part:

- Pocket

- Tool change

- Rough

What did I miss? Any help is very appreciated.

workspace_coffee.kmz (410.9 KB)

The tool change is because the parts are considered independently and the process chain is performed for each in order. KM has a trick for this. Once your space is laid out the way you want, open the tools → mesh menu and export the STL. Will merge all your parts into one. Then delete the parts and import the newly exported STL. In your case, you’ll have to re-add the tabs and re-select the two pockets. Then preview. Here is the before (what you’re seeing) and the after.

BEFORE (YouTube)

AFTER (YouTube)

1 Like

And, yes, there should be a checkbox that allows you to consider the entire workspace instead of individual parts for processing order.

1 Like

Perfect and thank you for your reply

![]()