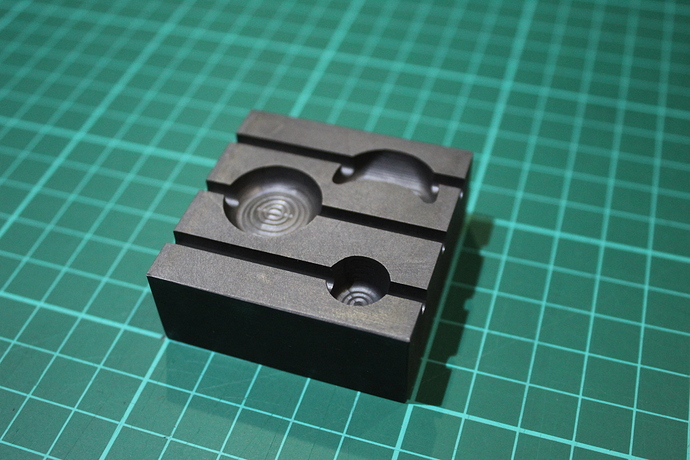

wow. that looks great. so smooth.

very nice! I noticed the air cooled spindle and thought there’d be more graphite blown around but instead it’s piling up nicely on the sides. So you not only get a glass bead mold you get some graphite lubricant too.

Curious, what kind of rod to you place in the slot to remove later and is it preheated or something so contraction provides ability to remove?

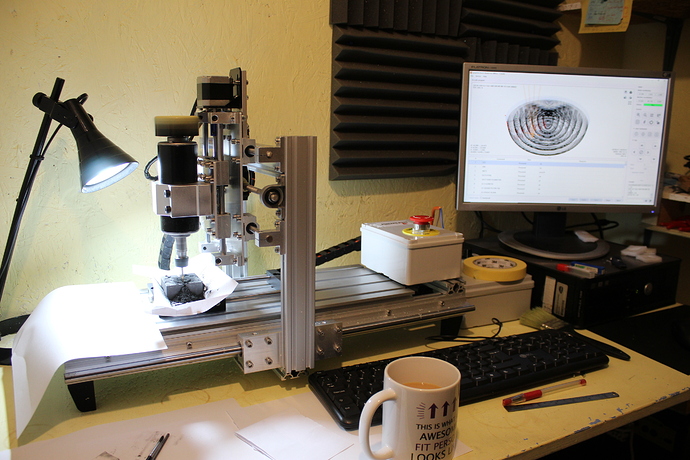

What mill did you use?

Thanks. I taped up the fan at the top with masking tape and that kept the dust down. I also dialled down the spindle speed to about 5 or 6K, and only 150mm/min and 0.3mm cut depth per pass.

Heat build up wasn’t a problem as the motor load was quite low. Graphite dust gets everywhere and really hard to clean up, which it probably why it’s a good dry lubricant! I used a lot of paper shields to contain it so it was easy enough to clean up.

I made these as a trial mould for a glassmaking friend in Germany. I used a 3mm ball nose, and a 3mm slot for the rod so there could be some sticking issues. Maybe a smaller 2.5/2.8mm rod will work better. Let’s see - I’ve posted the mould, so hopefully I can give an update one it’s been tested.

Made using my own design machine, the Minimillr (see minimllr.com)

And it’s a very nice looking machine. The first thing I look at is how the spindle is mounted and you have some nice wide spacing of the linear rods. Next is where the linear rods are along the Y axis. Far too many put them up above where debris from milling gets all over them and you put them down low below the bed. The only thing I see is that the bed could have extended slight overhanging those linear bearings or something to help ‘cover’ them. Otherwise it looks very well done.

Unfortunately the link you provided for the MiniMillr does not work. This does - https://minimillr.com/