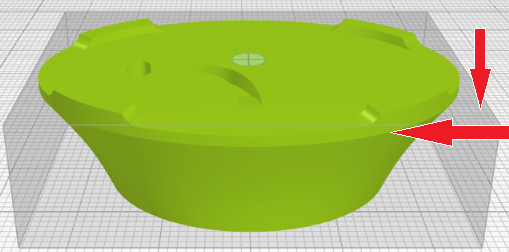

This part is being processed Bottom First. See image. Once the bottom is complete it is flipped over and placed into a jig for XY. I’m wanting to do one of two things.

- Clear stock around the part perimeter completely

- Clear stock with a much wider cutout, specified

#2 allows for an easier post process to cut off the remaining waste stock.

I would also like it to start on the outside (furthest most from finished edge) and work it’s way into the finished edge. Perhaps with an option to always make the final pass with only a few mills (specified) of material left from previous path.

workspace (1).kmz (902.9 KB)

As a note: I have to change bits between passes so I try not to. The machine is hobbyist grade. Zeroing is microswitches and not accurate enough.

1 Like

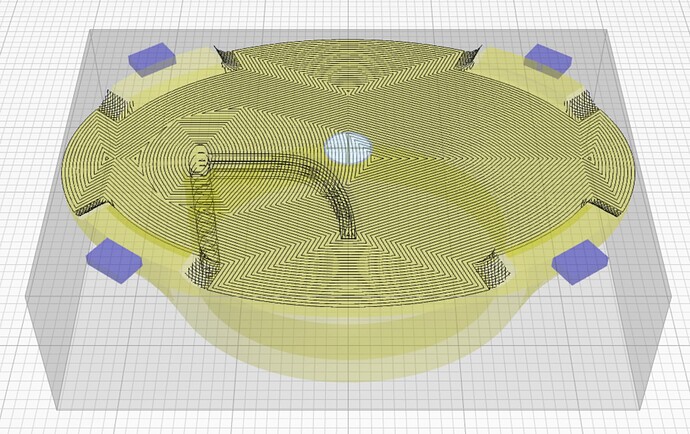

I see what you’re saying. The wide cutout option is processing inner first. I’ll mark that as a bug to fix. Roughing operations have a “leave stock” option which provides the XY axis offsetting you’re looking for. Perhaps a combination of ops can achieve this. It looks like you may have found the flip operator. See attached proposed workspace. I don’t know your setup or constraints so this could be off the mark.

When importing workspaces, I recommend opening a new page in your browser’s incognito mode so it doesn’t override any of your other settings.

proposal.kmz (859.1 KB)

This is what I’m trying to accomplish.

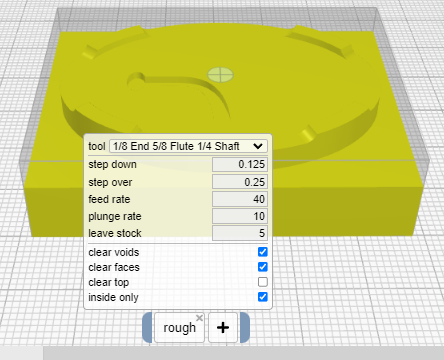

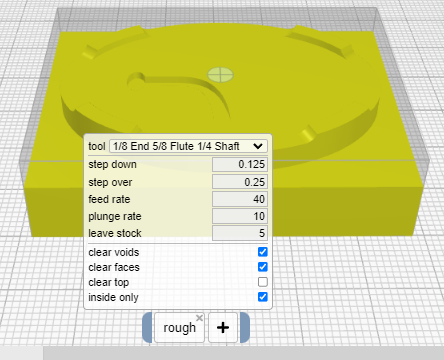

When I ask rough to leave stock it does not create tool paths.

How is this accomplished?

workspace (1).kmz (446.1 KB)

I think you’re using imperial? if so, that setting is asking for 5" of stock to be left. or everything in this case. try a setting like 0.01 – keep in mind the entire rough op will leave 0.01 around the edges and should be cleaned up with an outline or contour pass

1 Like

I’m thinking mills not inches. Oops!