Will it update immediately even if I am accessing it through Onshape?

If you think so - I will go ahead and give it a go.

I haven’t made any changes to Kiri’s device profile until I can confirm what change is needed for the Ender6. I just changed the above file by hand. If you could use the gcode file I provided and try running it, that would be great. It’s not something you would do inside Onshape or Kiri:Moto.

Oops! Okay - I got your updated gcode downloaded. I promise I am not usually this dense. Thanks for all your help.

I will write back presently.

That works much much better! It appears to be printing successfully.

Two thoughts from watching it warm up just now.

Print head and bed warming happen simultaneously - and with the bed warming to 70C - printhead is hanging out at Z0 heated up for a bit before the bed catches up.

Is this intentional? I am used to warm up happening with Z a bit higher and then a pre extrusion clears the head before printing - or I can grab excess extrusion with tweezers. Have I been doing this wrong?

Also - I should warn any onlookers that this G-Code is for an unfinished D-6. I wanted something quite simple to attempt - it is not worth printing.

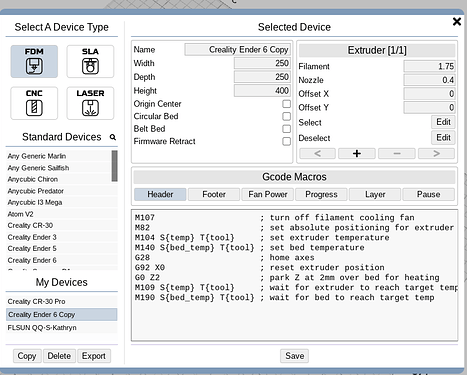

great. very interesting. parking at Z > 0 is trivial to add to the header. I will update the device profile and push it out later today. in the meantime, if you want to customize the Ender6 device and modify the header macro yourself, try this:

M107 ; turn off filament cooling fan

M82 ; set absolute positioning for extruder

M104 S{temp} T{tool} ; set extruder temperature

M140 S{bed_temp} T{tool} ; set bed temperature

G28 ; home axes

G92 E0 ; reset extruder position

G0 Z2 ; park Z at 2mm over bed for heating

M109 S{temp} T{tool} ; wait for extruder to reach target temp

M190 S{bed_temp} T{tool} ; wait for bed to reach target temp

the cura-generated code includes a purge line on the side of the bed. this is extracted from the file you provided, if you want to append that to the header:

G92 E0 ;Reset Extruder

G1 Z2.0 F3000 ;Move Z Axis up

G1 X10.1 Y20 Z0.28 F5000.0 ;Move to start position

G1 X10.1 Y200.0 Z0.28 F1500.0 E15 ;Draw the first line

G1 X10.4 Y200.0 Z0.28 F5000.0 ;Move to side a little

G1 X10.4 Y20 Z0.28 F1500.0 E30 ;Draw the second line

G92 E0 ;Reset Extruder

G1 Z2.0 F3000 ;Move Z Axis up

Thank you! This is so helpful - I really appreciate all your time this morning. I am excited to get kids independently printing on these machines with Kiri:Moto!

Also - There doesn’t appear to be a built-in Ender 6 profile on Cura, so Kiri:Moto is my new slicer!

Edited:

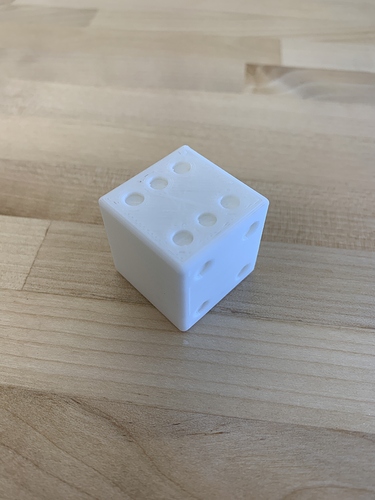

Here is the finished print - I noticed the is a little gap between walls and top layer. Certainly looks pretty enough for my purposes.

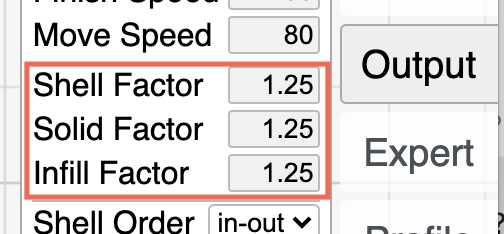

increase the flow rate to close any gaps. this may require experimentation depending on firmware settings and filament density.

I am so sorry to be having troubles printing again.

I have tried multiple files exported from Kiri:Moto with my updated header that I saved and pasted in. (I also tested on multiple Ender 6 machines just to make sure it wasn’t a belt issue.)

I checked the gcode as well as I could, and it looks like the instructions are correct.

https://drive.google.com/file/d/1MC8JO5cwdPWMk67cG3D_vovQJ46ADIT1/view?usp=sharing

When I print all the extruder does is hang out on the right side of the bed and move back and forth indefinitely.

Here is a link to a video showing the issue.

https://drive.google.com/file/d/1JG-0Uw2CIIvxGeIzvm_D_o2Mruhsd-rG/view?usp=sharing

yesterday you were able to print using files generated by Kiri:Moto but not today?

Unfortunately I was only able to print the one you edited and sent me.

The ones where I pasted in the header into Kiri:Moto didn’t work - but I didn’t know that until it was time to go home, and I figured it might be my error, and I should try again this morning.

Yes! that is definitely what I want to print - I just can’t figure out why it won’t print.

I thought it might be the additional header gcode you sent me to print a pre-extrusion line, but that isn’t in the gcode, the profile is saved, and I have no idea why the Ender 6 is being so difficult.

The only difference I can find between the two gcodes is line 93. G92 E0 versus G92 X0

Edited:

I changed my file to E0 instead of X0 and it worked!!!

typo above on my part then. sorry bout that. the updated device profile that I checked is correct.

When/how do device profile updates happen? When will I see the new Ender 6 profile in Kiri:Moto?

Thanks again for all your help. I felt quite proud eventually figuring out what to do to fix the issue I was having!

I’m pushing an update in a few hours. Usually I push new code 1 or 2 times a week.

Hey Stewart,

I am continuing on my journey to having an Ender 6 profile that prints flawlessly without a lot of settings editing, so I am here today to talk retraction settings.

This profile has a horrendous stringing issue with PLA. It happens regardless of filament or Ender 6 that I attempt to print on. I have toyed with temperature - and best seems to be 200-205 nozzle and 60 bed for most PLA filaments.

5.5 is the amount of retraction - and that seems reasonable, but that only leaves the retraction speed as the source of the issue. It says 60 - but the gou.stl that came with the printer says 3600 is the retraction speed listed in the gcode - in mm/s.

I tried changing the retraction speed to 3600 and didn’t notice a big difference - only that the printer is much noiser retracting at those speeds!

Do you have any suggestions for how to reduce stringing? I know there must be something I am missing.

Thanks again for all your time.

Kathryn

I think by 3600, they mean 3600 mm/min which equals 60 mm/s in Kiri:Moto settings. The extruder won’t be able to move filament at 3600 mm/s. Firmware would limit that, anyway. So any number over the firmware limit would just use the limit value.

Retractions over 5/6 mm risk clogs and other problems. So my guess is that you may have a loose bowden coupler or tube that’s causing stringing.

I have a 6 of these printers - and four different brands of filament and the stringing issues is happening on all of them all the time. I can’t imagine that they all have clogs and other problems. I have been using 5.5 retraction and 60mm/s settings.

Lowering the nozzle temp to 200 helps a bit - but not enough.

If you are able get a cleaner print from any other slicer, then I should be able to trivially figure out from their gcode what they’re doing differently.