Hi all,

I’m working on a Gothic style chessboard and I’m using my Makera Carvera Air and Kiri:Moto to mill the pieces, I started with the horse as I think it’s the most difficult piece and not too tall so it takes less stock. It is my intention to make all pieces and the board by milling on my Makera Carvera Air and to document my progress here each time I have a piece ready.

I found a few bugs in the milling operation and Stewart was really quick to fix the issues I ran into making the lathe function way better.

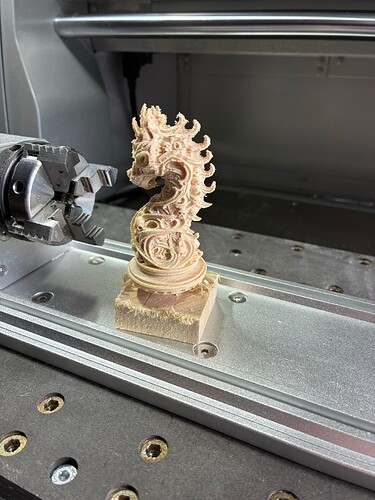

I made this test piece out of Basswood / Limewood after milling I did nothing more than remove the dust this is how it came off the lathe.

You can see that with the lathe you can’t reach the very top, but it’s for like 80% done, I can remove the rest of the stock with a sharp knife.

Then you can also see the limit of 4-axis milling underneith the chin of the horse, there is a little bit of stock left the CNC just can’t reach. shouldn’t be too bad to remove that by hand either.

I’m thinking about making the the white pieces out of Beechwood and the “black” pieces out of purple heart (I need 2 kinds of wood with around the same density so the pieces would weigh roughly the same, this Basswood is nice lookig, but the piece feels too light when moving it.

I already have bought the Beechwood, I’m just waiting on the table-saw I ordered to cut it into the right size stock.