Hey guys! Are there any Kiri:Moto users with Prusa i3 MK3S+ printers, who have an awesome Kiri slicing profile for it? ![]()

I’d love to steal it! ![]()

How different is it from the MK2S profile included? Did you try customizing it?

Dunno how different it is, but trying the MK2 profile did not result in a good print, sadly.

drop the gcode for a simple cube or something that does print well on the MK3S+ here and I’ll analyze it

these settings in the gcode header seem particularly relevant, as they configure firmware behaviors governing print quality. why this is left up to the slicer is perplexing. the config from the factory should be good without it.

the print is also quite slow (30-50 mm/s)

M201 X1000 Y1000 Z200 E5000 ; sets maximum accelerations, mm/sec^2

M203 X200 Y200 Z12 E120 ; sets maximum feedrates, mm/sec

M204 P1250 R1250 T1250 ; sets acceleration (P, T) and retract acceleration (R), mm/sec^2

M205 X8.00 Y8.00 Z0.40 E4.50 ; sets the jerk limits, mm/sec

M205 S0 T0 ; sets the minimum extruding and travel feed rate, mm/sec

M862.3 P "MK3S" ; printer model check

M862.1 P0.4 ; nozzle diameter check

M115 U3.10.0 ; tell printer latest fw version

G28 W ; home all without mesh bed level

G80 ; mesh bed leveling

We’re already printing quite slowly, and we’re pretty sure all the configured values were like this as well - unless Prusa resets the settings (should save them from last test print we did).

We’re gonna try a print now with the GCODE stuff you quoted via. Kiri.

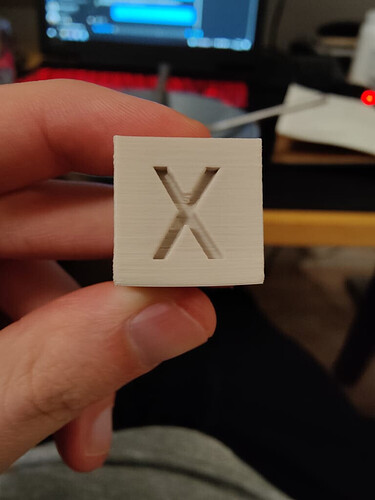

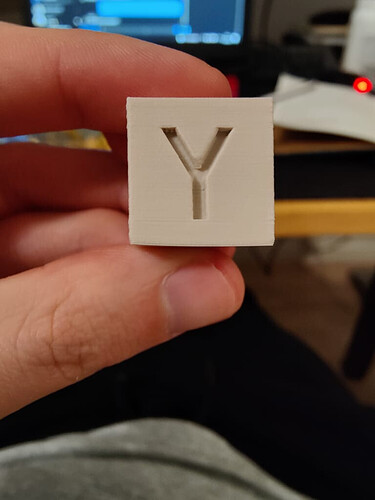

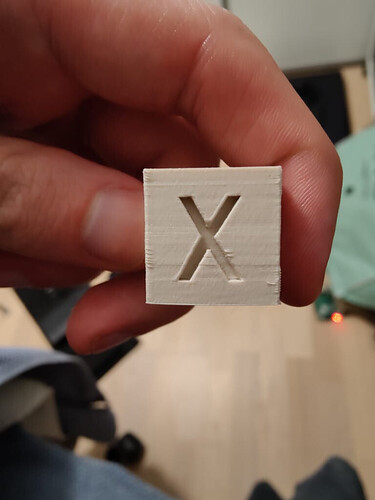

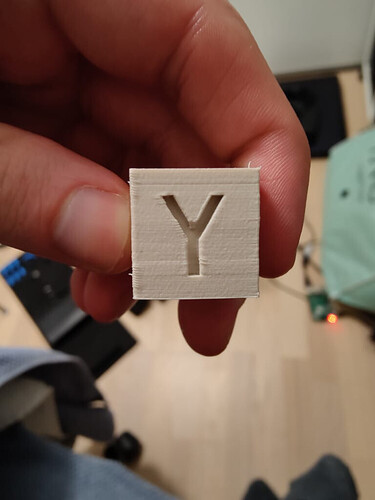

This is the same Calibration cube printed via. Kiri - with the best settings we’ve found so far;

xyzCalibration_cube-013.gcode (792.4 KB)

Same fugly result with the quoted start-GCODE, when printing via. Kiri

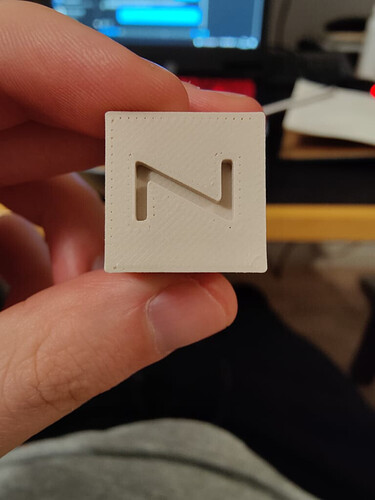

it looks under-extruded. in fact, running the two gcode files through an analyzer, it reveals that the gcode output by Kiri:Moto

a) feedrate is 25% faster than Prusa’s (slow it down)

b) extrusion factor is 87% of Prusa’s (increase flow factor)

c) infill density is a lot lower (easily visible in preview)

these are simple parameters to tweak in KM

there are other subtle differences

So, this is what I’m hearing from my colleague currently doing the testing regarding this;

We have tried extruding more, but some parts of the print just gets too much plastic, resulting in the print completely failing.

Even though the Kiri one is not the most pretty one, it’s the settings we’ve found where it fails the least.

To achieve a pretty print that has a high success rate is of course preferred.

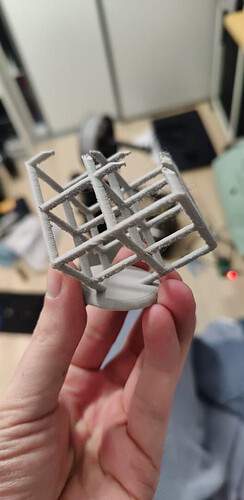

We’ll try to correct the things you mention, but last time it looked more or less like this; (another print, but still)

send an MK3S+ and I’ll fix this right up ![]() did you re-run the print with the new settings and the updated header w/ firmware settings? they could help mitigate the blobbing which looks like nozzle pressure management.

did you re-run the print with the new settings and the updated header w/ firmware settings? they could help mitigate the blobbing which looks like nozzle pressure management.