Hi,

I have an old Denford machine that I have outfitted with a open build black box.

I wanted to use kirimoto to run some jobs, but I’m having some trouble getting everything to work. I have my g code filed from kirimoto and I have framed it and confirmed the zero origin on my machine.

When I run the job it just sits there and then if I pause it and then start it again it will start its first cut but it will not start the spindle.

I guess really. My question is what are the general steps to make sure that the profile I’ve started in kirimoto is actually going to play nice with my g code sender.

I have not used this box before. Does it run Marlin or GRBL? Have you been able to run other gcode through it successfully? Do you have a gcode reference for what it implements? KM just produces the gcode files. Uploading those files to your sender and running them is highly dependent on your setup.

1 Like

Yea, it is a GRBL box.

I exported some g-code from carbide create using The GRBL post-processor. It seem to do the trick. I suppose in retrospect I may have gotten lucky.

I’m not sure what you mean by g-code reference for what it implements, but I think maybe it is this?

Supported G-Codes in v1.1

G0, G1: Linear Motions

G2, G3: Arc and Helical Motions

G4: Dwell

G10 L2, G10 L20: Set Work Coordinate Offsets

G17, G18, G19: Plane Selection

G20, G21: Units

G28, G30: Go to Pre-Defined Position [运动到预定义位置]

G28.1, G30.1: Set Pre-Defined Position

G38.2: Probing

G38.3, G38.4, G38.5: Probing

G40: Cutter Radius Compensation Modes OFF (Only)

G43.1, G49: Dynamic Tool Length Offsets

G53: Move in Absolute Coordinates

G54, G55, G56, G57, G58, G59: Work Coordinate Systems

G61: Path Control Modes

G80: Motion Mode Cancel

G90, G91: Distance Modes

G91.1: Arc IJK Distance Modes

G92: Coordinate Offset

G92.1: Clear Coordinate System Offsets

G93, G94: Feedrate Modes

M0, M2, M30: Program Pause and End

M3, M4, M5: Spindle Control

M7* , M8, M9: Coolant Control

M56* : Parking Motion Override Control

(*) denotes commands not enabled in config.h by default.

KM is used with a lot of GRBL machines. I have one as my primary CNC mill. So the gcode it creates should work just fine. If you have an example of a “working” gcode and one that KM outputs that doesn’t work, we can compare and try to figure out what’s up

1 Like

This might be wildly embarrassing, but I looked through the KM g-code and I didn’t see the M3 command in the code to turn on the spindle.

I imported a picture and tried to do a raster. I might just not know how to use KM.

I will use it from the onshape plugin and make a simple STL to test.

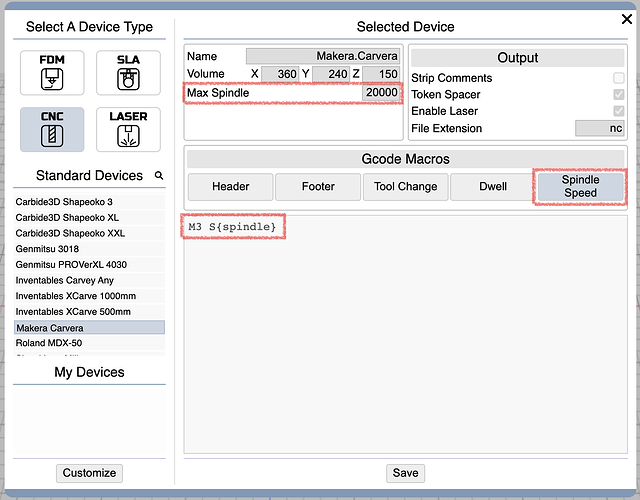

Check your machine definition. Make sure your have a max spindle speed set and that the spindle speed macro is not empty.

1 Like

That was it. I will reslice and test. Thanks.

1 Like