I defined a 15 degree taper bit with a 2 inch flute. Tried to rough out a very file part, a LOGO. The LOGO is 20 mils thick.

It looks as though the thickest part of the flute is limiting the tool paths.

Defining a 5mil end mill routes the detail.

Shouldn’t it use the diameter of the taper at a given depth. Limiting the depth so remove material but also limit depth based on diameter.

workspace.kmz (721.9 KB)

Unfortunately, the only operation that models the true tool geometry is contouring. Roughing, Outlining, Trace, etc all use the thickest part of the bit for offsetting. To do otherwise is really difficult. For this part, I would recommend defining a custom bit that’s just the offset at the depth the tip will be cutting.

1 Like

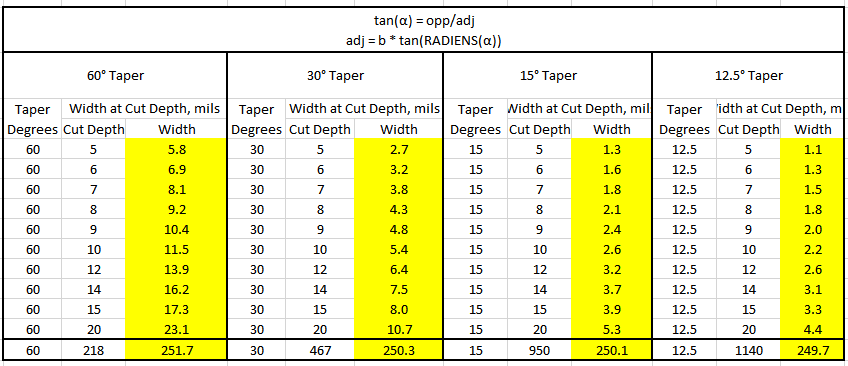

I’ve learned a fair amount about carving fine profiles. Now I have a calculator that defines the V Bit (taper) with at various cut depths. Technically speaking a 15 degree V Bit with a sharp point should route the detail in 16 minutes. Time to try it out. That being said, it seems typical tip diameter is 5 mil. The narrower cutting paths are under 5 mil. So I suspect too much detail will be lost on this 1 inch logo. Worth a try.

1 Like

Clearly I was trying for the impossible. And sure enough it routed but not legible.