By now I have generated gcode with LaserWeb (some 2.5D parts) and Fusion 360 (more complex shapes). Today I jumped into Kiri:Moto and fell in love with the import option for STL files.  I’m amazed with the options this tool offers.

I’m amazed with the options this tool offers.

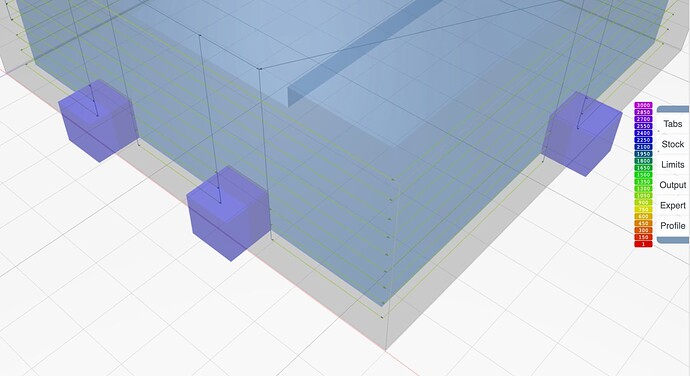

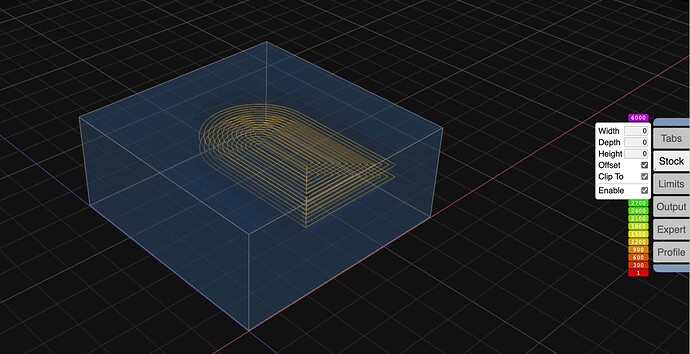

I think I’ll use Kiri:Moto mainly with my MaslowCNC. Therefore, I work with sheets of wood. Today I tried to generate the paths for a test part:

- The material is 18mm thick

- I don’t want to mill the top and back surfaces

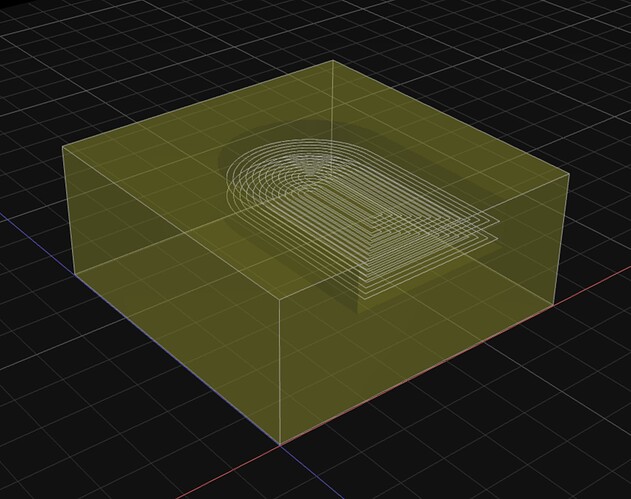

- I want to mill the pocket, which is 2mm deep

- and I want to mill the outline and extend it to 18.5mm (to make shure everything is milled off)

How can I extend the outline? I tried it with “Limits / Z thru” but that did not seemed to work. I’,m happy with all your hints. If I can fix this, then “Kiri:Moto” will be THE tool for simple CNC parts.

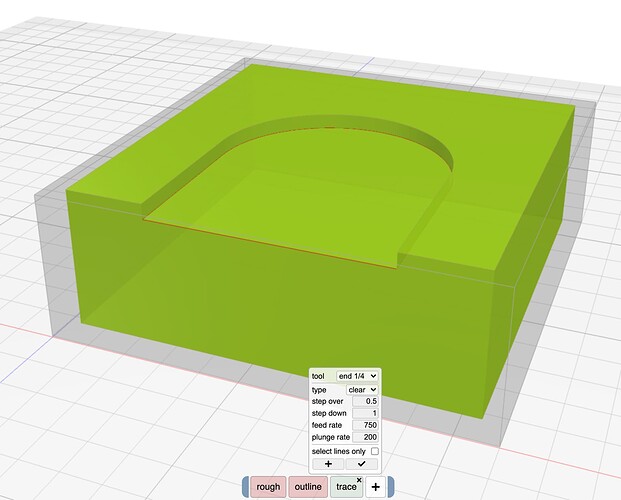

hi @enhydra and welcome! it should be possible to use the trace operation in clear mode to select the path around the pocket and have only that milled. then you can use the outline operation with z thru to perform the cut-out.

that is, if I’ve correctly understood what you’re hoping to achieve.

1 Like

two other options:

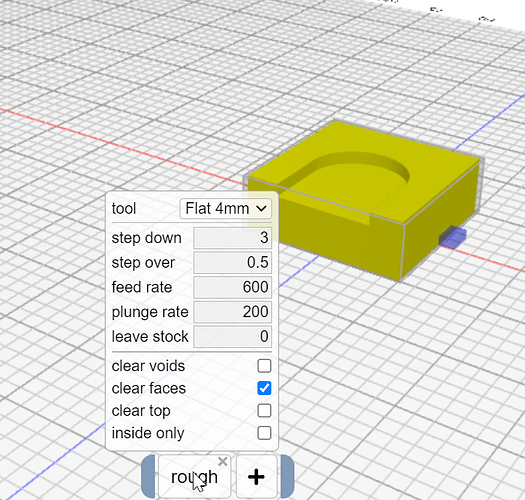

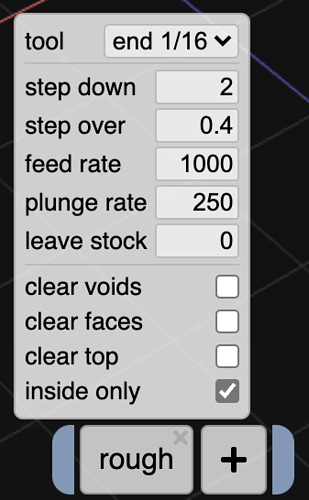

check inside only on the roughing operation accomplishes this.

also, and peculiar to this geometry, you can use clip to option on stock and set the stock offset to 0 to limit roughing to just that region.

1 Like

Hi Stewart

Thank you for your quick reply.

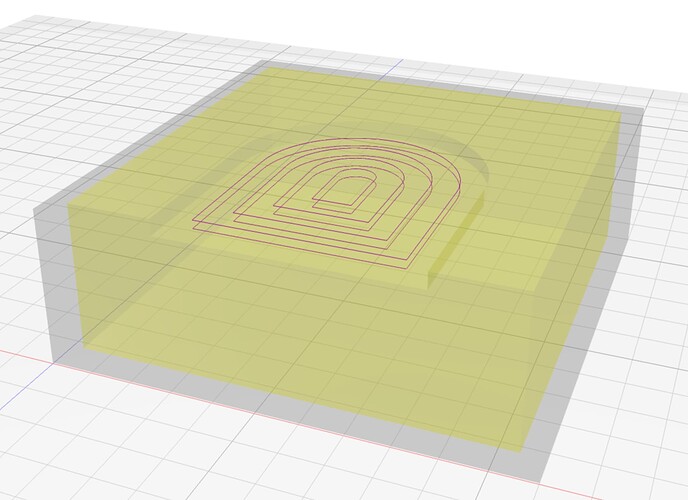

Selecting the path around the pocket did not really work. I was able to select the straight lines but not the segments of the arc. Outline and z thru worked very good.

I’ll test the other options tomorrow.

Hm, that’s strange. It only mills the pocket when I also check “clear faces”.

sometimes options on the same op come into conflict. it seems like a simple enough part. mind sharing the STL?

going back to an earlier suggestion, I was able to select the pocket using the trace op. did you have select lines only checked?

I haven’t been able to replicate cut direction changes in 3.2 with tabs on this part  If you right-click export workspace and share it, it may help me identify the setting at fault.

If you right-click export workspace and share it, it may help me identify the setting at fault.

OK, got it. Works like a charm.  Sorry

Sorry

I’m amazed with the options this tool offers.

I’m amazed with the options this tool offers.

If you right-click export workspace and share it, it may help me identify the setting at fault.

If you right-click export workspace and share it, it may help me identify the setting at fault.