I think I have everything setup correctly for my printer. I went through all the settings I could think of and basically tried to duplicate my Cura settings, even have my BL touch doing its auto leveling at the start of a print. However it seems no matter what I do the extruder doesnt…extrude.

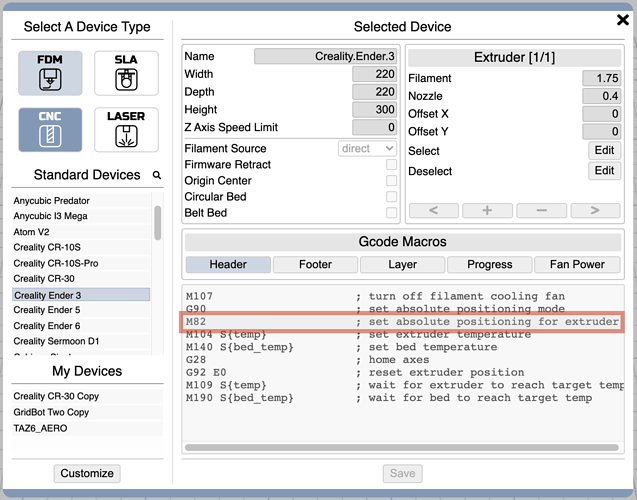

I don’t know if the E3 firmware allows switching between relative and absolute extruder positions. This is controlled with M82 and M83 in the gcode header under device settings. If you don’t have one or the other in your header, please add it. And if you do have one, try the other. In theory, it shouldn’t matter which one is used. Most firmwares respect both.

Wow, how did I miss that. I copied my Code line by line from Cura and I somehow missed that one line. I use M82 in Cura, but have neither in KM…let me fix that and try again.

Sorry I wrote that backwards. I have M82 in KM, but I have neither in Cura and Cura slices fine. Ill put the 2 codes below for comparison.

Kiri:Moto

M104 S{temp} ; set extruder temperature

M140 S{bed_temp} ; set bed temperature

M107 ; turn off filament cooling fan

G90 ; set absolute positioning mode

M82 ; set absolute positioning for extruder

G28 ; home axes

G92 E0 ; reset extruder position

M109 S{temp} ; wait for extruder to reach target temp

M190 S{bed_temp} ; wait for bed to reach target temp

G29 ; Auto bed-level (BL-Touch)

G92 E0 ; Reset Extruder

G1 Z1.0 F3000 ; move z up little to prevent scratching of surface

G1 X0.1 Y20 Z0.3 F5000.0 ; move to start-line position

G1 X0.1 Y200.0 Z0.3 F1500.0 E15 ; draw 1st line

G1 X0.4 Y200.0 Z0.3 F5000.0 ; move to side a little

G1 X0.4 Y20 Z0.3 F1500.0 E30 ; draw 2nd line

G92 E0 ; reset extruder

G1 Z1.0 F3000 ; move z up little to prevent scratching of

Cura:

; Ender 3 Custom Start G-code

M117 Getting the bed up to temp!

M140 S{material_bed_temperature_layer_0} ; Set Heat Bed temperature

M190 S{material_bed_temperature_layer_0} ; Wait for Heat Bed temperature

M117 Pre-heating the extruder!

M104 S160; start warming extruder to 160

G28 ; Home all axes

M117 Auto bed-level begin!

G29 ; Auto bed-level (BL-Touch)

G92 E0 ; Reset Extruder

M117 Getting the extruder up to temp!

M104 S{material_print_temperature_layer_0} ; Set Extruder temperature

M109 S{material_print_temperature_layer_0} ; Wait for Extruder temperature

G1 Z1.0 F3000 ; move z up little to prevent scratching of surface

G1 X0.1 Y20 Z0.3 F5000.0 ; move to start-line position

M117 Extruder self test and clearing!

G1 X0.1 Y200.0 Z0.3 F1500.0 E15 ; draw 1st line

G1 X0.4 Y200.0 Z0.3 F5000.0 ; move to side a little

G1 X0.4 Y20 Z0.3 F1500.0 E30 ; draw 2nd line

G92 E0 ; reset extruder

G1 Z1.0 F3000 ; move z up little to prevent scratching of surface

; End of custom start GCode

When you look at the gcode output by KM, do the E values only increase as you progress through the file to the end?

I posted both start Gcode files above.

Yep. I’m interested in the gcode in-between to see what KM is actually generating. Perhaps DM that to me.

Ah, ok Ill DM it to you.

The KM generated gcode you sent printed properly. I suspect there is something else going on with your printer.

I believe I found the “issue” it was me, lol. I was slicing from my iPad not realizing I hadn’t imported the latest profile from my computer.

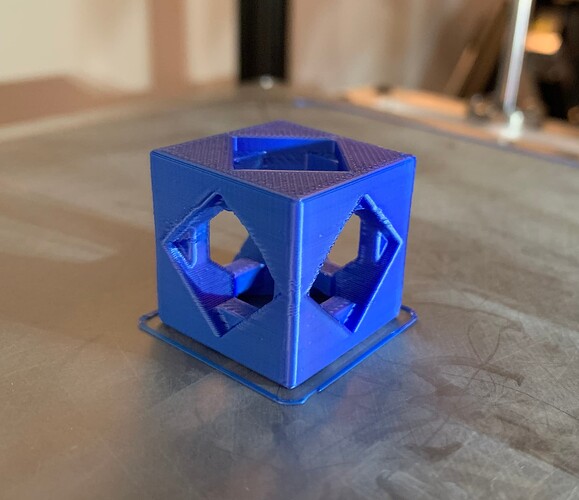

Ok, I am noticing an issue now that I’m actually printing. Anything I slice with KM seems to print much faster than things I slice with Cura despite them both being set to 50mm/s…There must be something I’m missing here.

cura may be manually compensating for lack of firmware nozzle pressure management by limiting speeds and applying acceleration / deceleration segments. it may also have a minimum layer time setting. and for the cube, each layer prints quickly, so the slicer slows down the print to allow for cooling. you can achieve similar results with the short path and min speed settings under Expert.

what about the Shell Factor, Solid Factor, Infill Factor under output?

What should I adjust them to? I’ve watched the Youtube video, and looked through the docs and I dont really know what these settings do, or what to adjust them to.

I am currently printing a “baby groot” figure scaled down in KM from 1 to 0.3, and I noticed it was printing too fast in the beginning on the legs, and now that its up higher into skinnier areas its much slower, more like normal.

short path of 50 means linearly slow perimeters less than that length (in mm) down to min speed. so things like legs will print a lot more slowly. try 50 / 5

the shell, solid, fill factors are multipliers on the amount of plastic extruded per mm. if you get bulges or inconsistent layer lines, try reducing it closer to 1. keep the values in sync until you get good prints. then optimize.