Today I gave KM another try for an aluminum job to see if I can prevent any plunging meanwhile using helical operation and ease down. The answer is “almost”…

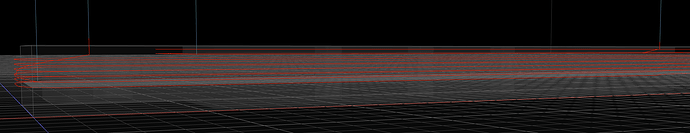

Ease down does a great job inside the material but unfortunately it is not applied every time the tool enters the material.

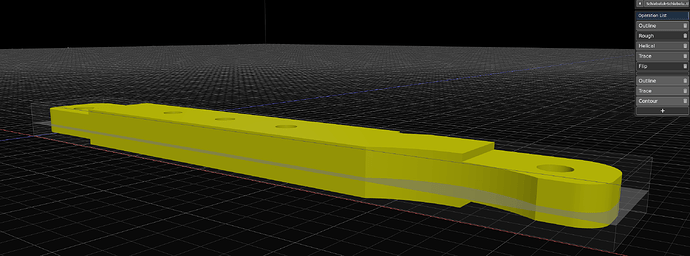

This is the part:

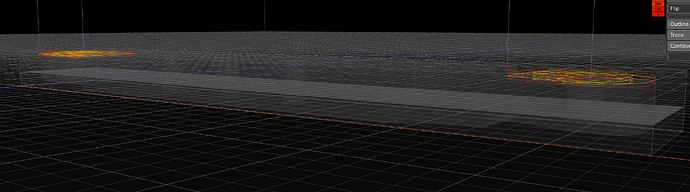

Doing a rough operation: At the far end, ease down is doing well but on the near end the tool plunges into the material.

This is similar with outline operation: Here we see a plunge first and then a nice ease down for the lower second part and inside the material: