Hi there Stewart,

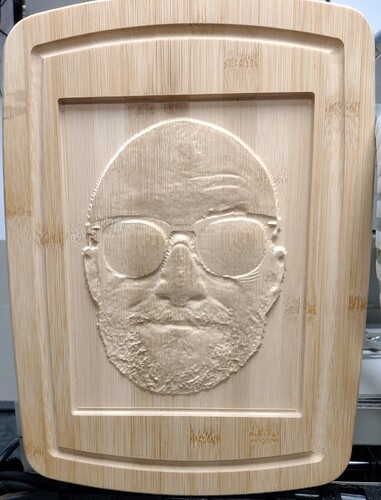

I’ve just started using Kiri:Moto to generate toolpaths for CNC contour routing and my first attempts have turned out far better than I expected, so I thought I’d share them in your showcase section as they wouldn’t exist without your fab software.

I never want to just use other peoples designs, so making my own stuff from photos seemed like an obvious starting point.

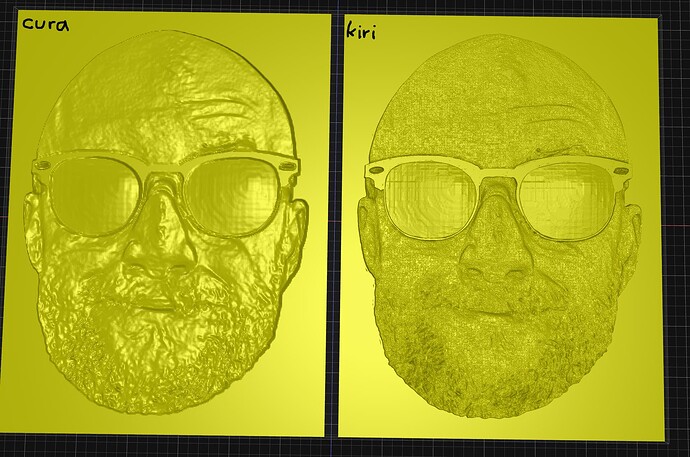

I’m absolutely delighted by Kiri:Moto, so far, I’ve gotten the best results by using a photo editor to mash the photos then CURA to turn them into STL files then K:M to generate tool paths. …but I have lots of experimentation yet to do.

I made Youtube videos of my efforts , heres one-

so THANK YOU.

Kiri:Moto is Fabulous software.

1 Like

That is awesome!! Thanks for sharing!

Have you tried importing the JPG or PNG directly into KM and letting it turn them into solids? There are a few parameters to tweak borders, inversion, etc. Memory is the main limitation, though. So you’d have to keep it under 1000x1000.

Hi !

Yes I have tried that and the solid that Kiri creates after importing a png looks amazing

However, I haven’t yet found a good combination of settings that work well for me with the Kiri .PNG import.

I tried adding various amounts and types of blur to the photos before import, and also various amounts of BLUR on Kiri-import, but I never really found a bunch of settings that produced as smooth and well behaved a toolpath as importing the stl from cura did.

Basically the cura method shown in the YT video just happened to have defaults that worked for me straight away so I ran with it.

- my pic was 1002 x 1328 pixels, so I guess I was over the limit for the Kiri import…

I’m sure I’ll be doing more of this so I’ll be trying various methods to see what makes the best looking toolpath for each project.

1 Like

Cool  If you try again, I’d recommend downscaling the image a bit (maybe 500 x 650) then trying a blur of 3-5.

If you try again, I’d recommend downscaling the image a bit (maybe 500 x 650) then trying a blur of 3-5.

1 Like

Cool. What machine and bit did you use?

Hi, glad you like it, I’m pleased with how well it turned out.

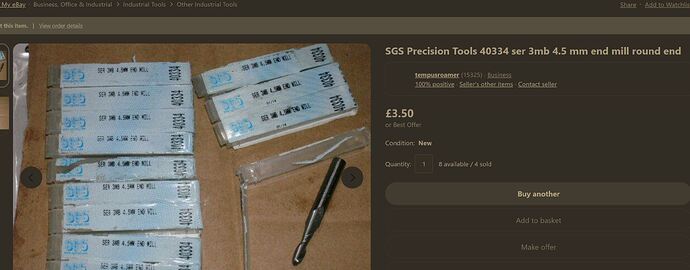

I used a 4.5mm diameter ball-end 2-flute high-speed-steel cutter, bought from ebay,

and the machine is like one of those 6040 table-top cncs, it was manufactured in china.

I modified the electronics to have an arduino running GRBL as it had a dodgy MACH interface card that required a parallel port interface and didnt work properly, and teh copy of MACH s/w supplied was an illegal copy… so I use UGS instead.

Best regards !

1 Like

![]()