Okay – I didn’t expect to find yet another place to adjust this behavior.

-

I assume that Output–>origin-center doesn’t really affect this, right? It doesn’t appear to. (I.e., that’s purely a 2D centering, right?)

-

I really would have expected the value you’re saying is in z top offset to be a property of the stock, not of the z axis. After all, it might change with every piece of stock.

-

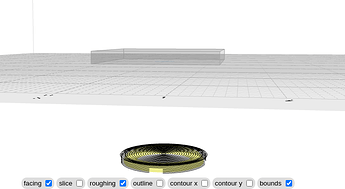

Sadly, it doesn’t work properly. My stock is .25", my part is .16", and if I set z top offset to .09, my part ends up something like an inch below the table

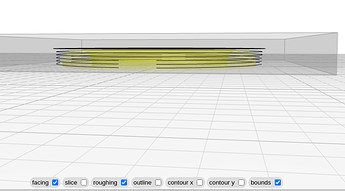

If I set z top offset to about .004, then it looks like the bottom of the part is pretty close to the table. Perhaps this is another inch/mm issue, but if so, it’s more subtle than my inner programmer can picture.

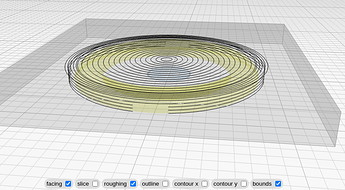

- You can see from the screenshots that even though .004" makes the bottom of the part line up (roughly, by eye) with the table, the roughing cut isn’t adjusted for the added depth of the first pass. It also roughs out the whole area of the part outline, rather than just the part’s silhouette. The first is a real problem, the second is obviously just a would-be-nice. (But maybe the first problem will go away when the previous bullet is fixed.)

Finally – is my preferred setup unusual? I’m surprised I have to do external math to set up something that seems so basic.