Hey Everyone,

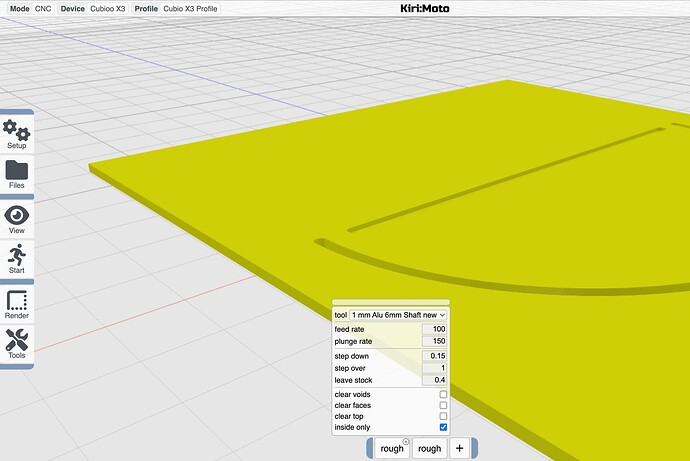

I received a new CNC a few weeks ago and I’m having difficulty creating a G-Code that does exactly what I want it to do. I used to different Postprocessors but since Kiri Moto was recommended by the manufacturer I switched and I’m really happy with the software.

But for this exact project I’m running into problems, The operation doesn’t cut the right depth on the 0.8mm Thick aluminum sheet. One Pocket is only 0.4mm deep but it cuts about 0.75mm deep. the other is a pocket that should be cut through the whole material thickness, but it keeps cutting for roughly another mm into the CNC bed.

I will upload the STL - The Workspace Data and the Tool Data.

Material : 0.8mm Alluminium

Tool - 1mm Aluminium Cutter 6mm Shaft Tool#19

Operation used to generate G-Code : Rough

Thanks a lot in advance