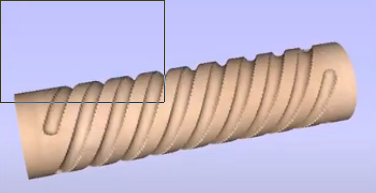

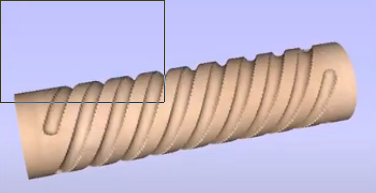

Can Kiri generate gcode to cut a spiral design out of stock in a rotary(A) axis from an STL ?

?

This is a LinuxCNC based 4 axis system.

Can Kiri generate gcode to cut a spiral design out of stock in a rotary(A) axis from an STL ?

?

This is a LinuxCNC based 4 axis system.

not yet. while it’s on my todo list, I don’t know when I’ll get to it

Have you run across anything that’ll run on Linux which can?

One of my projects is a design in 2x2" wood so I can break it down to 4 indexed steps of the rotary but the spiral would be better not indexed.

I personally have not had need of a 4th axis … or this would have been completed sooner

I hear you and concur but I know a guy who upgraded from a Shapeoko and spent >$15,000 on a 4(or 5) axis machine and with the training he got was how to use the 4th axis for making baseball bats and he’s been experimenting with it by making railing banisters and now table legs.

I’m not much different in that when I find something interesting I’ll investigate it. It’s how I found Kiri:Moto. So now I’m wanting to see how I can make a small version of his table leg using the LinuxCNC/Remora controlled CNC and it’s 4th axis. There’s not lots of 4th axis work going on except in machine shops and even then lots of those are just using the 4th axis to index a side of the design and do typical 3 axis machining to the side.

I just recently found that FreeCAD’s CAM plugin( Path workbench ) has a 4th axis helix function which might be the thing I need to get the toolpaths. I don’t know if it will lead to any ideas resulting in more 4th axis work but it’s a challenge I’d like to try to both learn more about this, learn more about LinuxCNC, get more design work in FreeCAD and hopefully show how a complete opensource workflow can handle these complex tasks.

I got rolled eyes when I dumped Fusion360 for FreeCAD after they made changes to licensing and were pulling features. I also saw similar emotions when I mentioned wanting to get all my machines running the same firmware and trajectory planning software. Got a few, “don’t you like LIghtBurn?” questions showing they don’t understand what LinuxCNC/Remora does even after I told them I still used LIghtBurn for generating the GCode. BTW, I’ve not tried Kiri yet for the laser and have plans to do that. I had to setup LInuxCNC to use M67 command for the laser control because changing the spindle speed caused large slowdowns in Trajectory Planner performance because spindled don’t instantly reach speed and changing spindle speed every .1mm( 254 DPI ) killed scanning performance.

that’s pretty inspiring. I already know how I plan to implement 4th axis controls. I think it’ll be relatively easy to use. just a matter of time.

Your approach to improvements to Kiri has worked well and improving the ‘normal’ stuff makes way more sense then the oddball stuff. That is until you find yourself interested and/or it scratches and itch which will also gain users because of it. I don’t think 4th axis stuff is that unless you’re doing something like you did with the bump maps, which is a very cool feature since it allows great 3D like results from grayscale graphics.

Being able to carve 3D scanned bust, or other 3D model, into a piece of round or square stock would be pretty cool. Just not what anyone is doing now.

In particular, Brad Collette @sliptonic, who maintains the Path workbench, has recently started working on 4- and 5-axis features in the Path workbench, but he’s starting with what you describe:

He writes:

Our first goals will be to support 3+2 milling. This will be an improved implementation of the early experiments. The additional axes are used to rotate the part to a fixed location so traditional operations like drilling and pocketing can be performed. Whatever we build here will also set the stage for eventual ‘continuous 5 axis’ where the tool-paths are calculated that include the rotary axes.

I like and use FreeCAD as well, but also I ended up discovering Kiri:Moto because it did a really nice job of handling a complex part that I couldn’t figure out how to make FreeCAD handle in the time I had available. Thanks @stewart ![]()

Thanks Michael that’s great news. Making it easy to do indexed 4th axis rotations all within one toolpath would be a great start. From what I’ve seen on other forums, machinists generate routines to rotate and then either repeat the toolpath on the new surface or call up another toolpath. Just as Kiri knows about the 3D model, FreeCAD has intimate understanding of the 3D model so generating a single toolpath to carve a 2+ sided design would really simplify what the operator needs to do.

Thrilled to hear this is an active goal. Thx