Hi

Version 4.0.32

I’m using CAM functionality (as an “application” from OnShape).

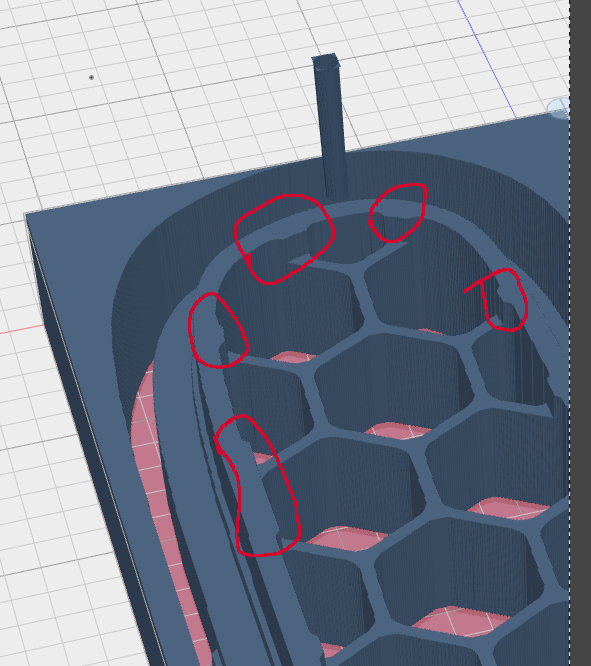

I am running a roughing operation, with “leave stock” set to 1mm.

Then running an outline operation which cuts most areas, eating into the 1mm left after roughing.

However it does not follow one perimeter, so the 1mm stock remains.

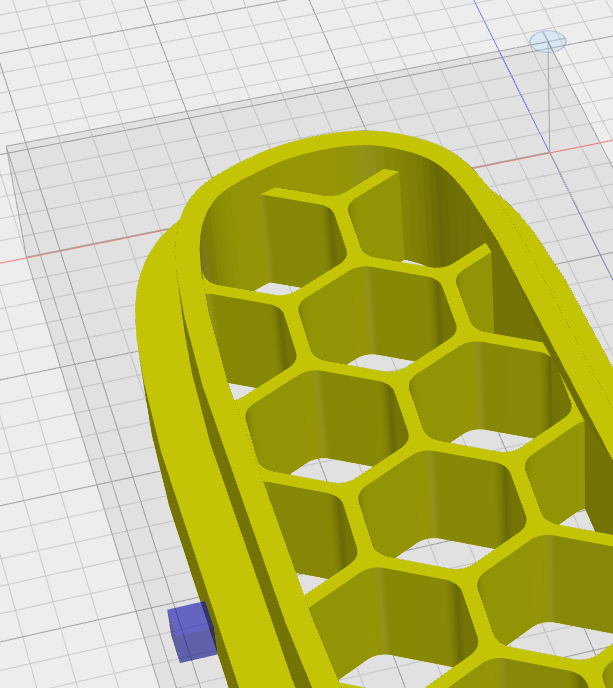

This is not easy for me to explain. I hope the pictures of the object and the animation output make it clearer.

As a workaround I am running a second rough operation at the end, with “leave stock” set to 0. This works but is inefficient as it spends most of the time cutting thin air.

I have tried all options that I can think of, but I can’t be sure it’s not my error. Apologies if it is a “me problem” - driving lessons welcomed.

I’ve mailed my KMZ file in anticipation.

Thanks