it’s not really obvious until you actually do a hands-on test and see what I was proposing. until then it seems like something important is going away. alas, it is simply removing confusing / redundant legacy stuff.

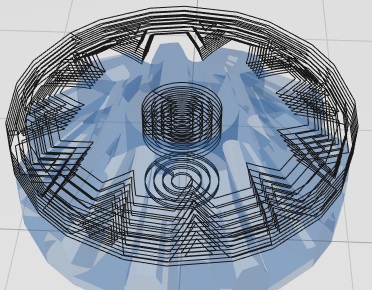

Still some repeated work in depth-first roughing.

In this example, the center void gets cut depth-firstly all the way down. Then the upper part of it gets cut again along with the upper layers – all(?) of which are cut breadth-first.

This clip shows a layer window that starts with the last few layers of the first cutting of the center hole and continues with the upper layers of inside roughing.

I’ll discord a settings-only export.

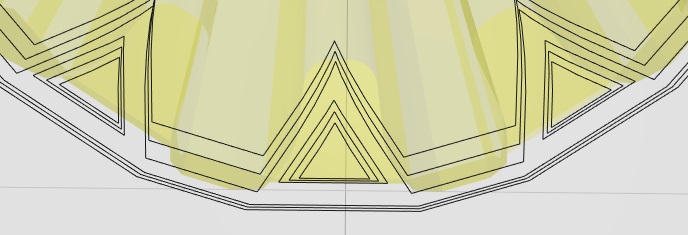

The main point here is the repeated work. As an aside: while I can see how the slicing of the upper layers mostly favors breadth-first cutting, it looks like there is some missed opportunity to cut depth-first triangle pockets in slices 4-6 which would save a chunk of vertical motion:

all will be fixed in the new routing code. the current stuff is not really fixable for this case.

Got it.

(20 char min)

The forum should have one of the those “badges” for this:

Earned ‘Hacker’!

Congratulations!! You’ve figured out how to get around one of our silliest rules!

About roughing/outline combinations, with a feature request:

Examples above show a part with a hole in it.

So far it appears that

- inside-only roughing will either cut a single outline inside the hole, or clear the void entirely

- outside-only outlining will cut 1 or 2 outlines inside the hole depending on “wide cutout”

For a setup that requires “wide cutout”:

- inside-only roughing must clear voids

- outside-only outlining will cut two outlines down the hole

It seems to me that in the outlining op, one or zero outlines inside the hole could make sense depending on whether or not a finishing operation is called for, but a second outline inside the hole is always superfluous.

I don’t see a way to do

- inside-only roughing

- outside-only “wide cutout” outlining with one or zero (not two) outlines inside the hole

And as I type this, I’m thinking of another reason to want to do outlining with zero outlines inside the hole. It seems like the 2.4 strategy for cutting the little gear example up this thread would be:

- inside-only roughing + “leave stock” + “clear voids”, coarse stepdown

- outside-only outline + “wide cutout”, coarse stepdown

- outline (not outside-only, not wide), fine stepdown

At the moment I’m thinking this should at least not break anything.

But some undesirables:

- ok for small voids

- no “leave stock” for perimeter vertical surfaces

- inside verticals (hole wall) get finished at coarse stepdown (maybe but not always ok)

- redundant offset outlines down the hole for wide cutout outlines

- many redundant outlines down the hole for 2nd outline op - which may burnish a hole wall cut at large stepdown, but probably won’t see enough stock remaining to do more than rub.

- same redundancy/finishing deal for outside perimeter vertical surfaces

I see there is an option to do inside-only outline without wideness, which will outline down the hole only

Here’s the 11th hour feature request…

I think it would help to have an outside-only outline option that excludes inside-only outlines, regardless of “wide cutout”.

That would allow something like:

- inside-only roughing + “leave stock” + “clear voids”; coarse stepdown

- outside-only outline + “wide cutout” + exclude inside-only outlines; stepdown for single pass at perimeter verticals

- outline (not outside-only, not wide), fine/surfacing stepdown – this op could be manually trimmed at the Z level where the outside perimeter coincides with the cutout outline

I think that would avoid re-redundancy and allow “leave stock” + finishing for (non-horizontal) surfaces other than the outside cutout perimeter. And not break anything.

if the inside hole is deep, then you want the double wide cutout for the same reason

there is explicitly a checkbox for this

if the hole goes through the part, it is considered outside because you will need to go through to free the part. if the hole is internal but not a thru-hole, then it does what you expect.

the rest are combinations that 2.5 will address.

Not sure what “same reason” refers to.

In the context where outlining follows inside-only roughing, for a setup that can’t cut deep slots, the hole is already cleared and there’s never any material for the 2nd outline to touch. Or so it seems. Because the prior roughing op must “clear voids” or die.

Yes. I think we are talking past each other.

If I may ask, how would you cut the small gear example in this topic in KM 2.4?

In the context where outlining follows inside-only roughing, for a setup that can’t cut deep slots, the hole is already cleared and there’s never any material for the 2nd outline to touch. Or so it seems. Because the prior roughing op must “clear voids” or die.

the various processes are not aware of each other, and so do no accommodate for work that may have occurred earlier. there are many reasons to use outlining alone without roughing (2d cutouts). and in that mode you may have the deep / hard material problem. agree that this creates duplicate work. hard to see how to avoid that without a lot more checkboxes.

If I may ask, how would you cut the small gear example in this topic in KM 2.4?

I don’t know the constraints of your setup. But the samples you sent me look reasonable. Perfection without a small amount of duplication cannot be achieved in 2.4

I think we’re still talking past each other.

I think we’re still talking past each other.

I guess the takeaway is to let 2.4 be what it is and wait to see where you’re going with 2.5/6.

There are temporary hacks I could employ to make this work for the use case you’re going after right now which I would have to undo in a week or two when I’m doing it the right way. I would argue there are scores of such cases.

I’d prefer to stay in a productive flow where coding time is spent moving forward. Far better stuff will come far faster. Caveat burning issues.